18650 Pil Kullanımları: Uygulamalara Tam Kılavuz

Muhtemelen fark etmeden onları görmüşsünüzdür.

Dizüstü bilgisayarınızın içinde saklanan, el fenerinizi güçlendiren veya en yeni elektrikli aracı sokağa sürdüren küçük silindirik piller.

Bahsettiğim şey 18650 pil kullanımları – ve bana güvenin, bu küçük güç merkezlerinin ne kadar çok yönlü olduğunu anladığınızda, her yerde fark etmeye başlayacaksınız.

Bu tam kılavuzda, bir profesyonel olarak 18650 pil paketi üretici, size 18650 pillerin en yaygın (ve bazı şaşırtıcı) uygulamalarını anlatacağım. Ayrıca, bu şarj edilebilir lityum iyon hücrelerinin neden taşınabilir, elektrikli dünyamızın bel kemiği haline geldiğini paylaşacağım.

Haydi başlayalım.

18650 Piller Neden Bu Kadar Özeldir?

Spesifik uygulamalara geçmeden önce 18650 pil kullanımlarıneden bu pillerin her yerde olduğunu anlamak değerli.

18650, boyutlarından adını alır: çapı 18mm ve uzunluğu 65mm. Ama boyut her şey değil.

Bu lityum iyon hücreler, o kompakt formda ciddi güç sağlar:

-

Yüksek enerji yoğunluğu: Çoğu alternatife göre daha fazla güç kübik inç başına

-

Şarj Edilebilir: Kapasite önemli ölçüde düşmeden önce yüzlerce şarj döngüsü

-

Standart tasarım: Markalar ve cihazlar arasında Evrensel uyumluluk

-

Kararlı voltaj: Boşalma döngüsünün büyük bir bölümünde tutarlı 3.7V çıkış

Sonuç? 18650 piller, performans, boyut ve maliyet arasında tatlı noktayı yakalar.

Ve bu yüzden onları tüketici elektroniğinden endüstriyel ekipmanlara kadar her yerde bulacaksınız.

18650 Pil Kullanımları

Tüketici Elektroniği: Her Şeyin Başlangıcı

Dizüstü Bilgisayarlar ve Taşınabilir Bilgisayarlar

2025 yılında herhangi bir elektronik mağazasına girin, ve büyük olasılıkla sergilenen dizüstü bilgisayarların büyük bir bölümünü güçlendiren 18650 hücreleri göreceksiniz.

Neden?

Basit. Dizüstü bilgisayar üreticileri şunlara ihtiyaç duyan piller ister:

-

İnce tasarımlara uyum sağlayabilen

-

Tüm gün pil ömrü sağlayan

-

Yüzlerce şarj döngüsüne dayanabilen

-

Maliyet etkin kalabilen

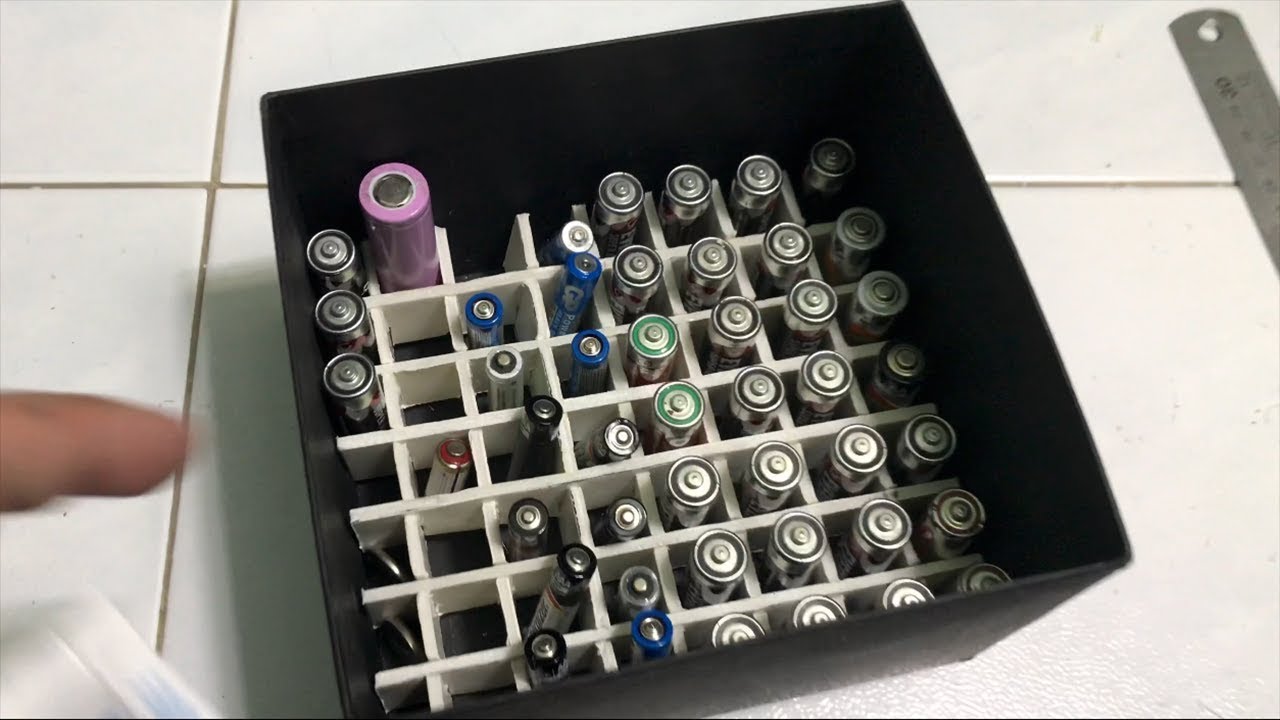

Tipik bir dizüstü bilgisayar pil paketi, 4-8 adet bağımsız 18650 hücreden oluşur ve birbirine bağlanır. Bu modüler yaklaşım, üreticilerin cihazın güç ihtiyaçlarına göre kapasiteyi kolayca ayarlamasına olanak tanır.

Örneğin, temel bir ultrabook, orta düzey pil ömrü için dört 2.500mAh hücre kullanabilir. Bu arada, bir oyun dizüstü bilgisayarı, uzatılmış performans için altı 3.500mAh yüksek kapasiteli hücre kullanabilir.

Güç Bankaları ve Taşınabilir Şarj Cihazları

İşte 18650 piller gerçekten parlıyor.

Bugün gördüğünüz çoğu yüksek kapasiteli güç bankası, birden fazla 18650 hücreyi paralel konfigürasyonlarda kullanır. Standart bir 20.000mAh güç bankası mı? Bu genellikle beş veya altı 18650 hücrenin birlikte çalışmasıyla oluşur.

Bu düzenlemenin güzelliği modülerliktir. Üreticiler, hücreleri ekleyerek veya çıkararak kapasiteyi kolayca artırabilir veya azaltabilir. Ayrıca, standart 18650 form faktörü, üretim maliyetlerini makul tutar.

Yüksek Performanslı Fenerler

Profesyonel fenerler ve taktik ışıklar, geleneksel AA ve D hücreli pillerden büyük ölçüde vazgeçerek 18650'leri tercih ediyor.

Sebep basit: güç çıkışı.

Tek bir 18650, 1.000+ lümen üreten LED fenerler için gereken yüksek akımı sağlayabilir. Bunu AA pillerle denemeyi düşünün – birkaç tanesine ihtiyacınız olur, bu da el fenerinizi hacimli ve ağır yapar.

İşte bu yüzden açık hava tutkunları, güvenlik profesyonelleri ve güvenilir aydınlatmaya ihtiyaç duyan herkes 18650 gücündeki ışıklara geçti.

Güç Aletleri: Kablosuz Devrim

Kablolu olmayan alet endüstrisi, 18650 teknolojisiyle tamamen dönüştü.

Bugün herhangi bir inşaat sahasında yürüyün, her yerde kablosuz matkaplar, testereler ve darbeli vidalama makineleri göreceksiniz. Bu aletlerin çoğu, 18650 hücreleri içeren pil paketleriyle çalışıyor.

Neden Güç Aletleri 18650'leri Seviyor

Profesyonel güç aletleri, şunları talep eder:

-

Motor çalışması için yüksek akım sağlayabilmek

-

Sık şarj döngülerine dayanmak

-

Zor koşullarda performansı korumak

-

Tutarlı güç çıkışı sağlamak

18650 piller tüm bu kriterleri karşılar.

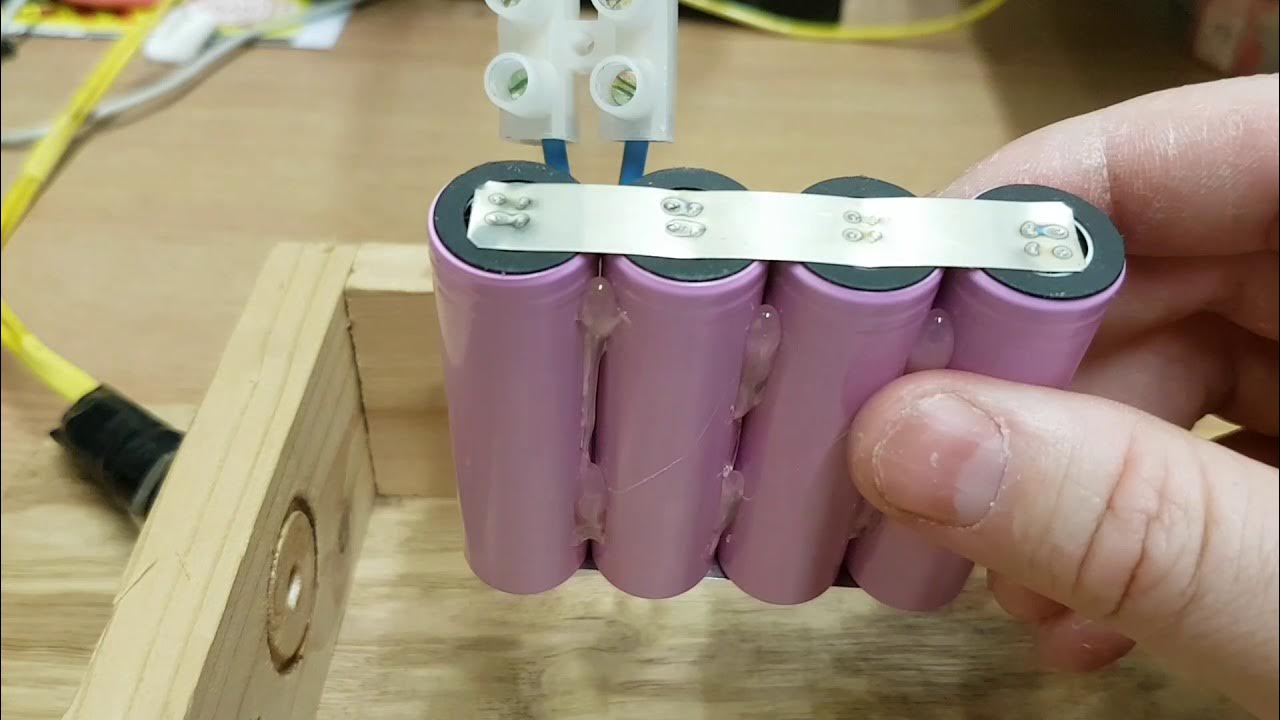

Tipik bir kablosuz matkap pil paketi, talep edilen uygulamalar için gereken voltaj (genellikle 18V veya 20V) ve akım kapasitesini sağlamak üzere 5-10 arası 18650 hücre içerir.

DeWalt, Milwaukee ve Makita gibi büyük alet üreticileri, 18650 tabanlı pil platformları etrafında tüm ekosistemler kurdu. Bu, bir pilin, ürün yelpazelerindeki birçok aleti çalıştırabileceği anlamına gelir.

Elektrikli Araçlar: Tesla Devrimi

İşte 18650 pillerin en büyük etkisini gösterdiği alan.

Tesla ilk Roadster'ı piyasaya sürdüğünde, devrim niteliğinde bir şey yaptı: özel pil hücreleri geliştirmek yerine, binlerce tüketici sınıfı 18650 pili kullandı.

Tesla’nın 18650 Stratejisi

Model S, ünlü şekilde bataryasında 7.000’den fazla Panasonic 18650 hücresini barındırıyordu. Bu yaklaşım birkaç avantaj sağladı:

-

Kanıtlanmış güvenilirlik: 18650’ler dizüstü bilgisayarlar ve diğer cihazlarda yıllarca gerçek dünya testinden geçmişti

-

Maliyet verimliliği: Seri üretim, hücre başına maliyeti düşük tuttu

-

Termal yönetim: Bireysel hücreler ayrı ayrı izlenip soğutulabiliyordu

-

Ölçeklenebilirlik: Hücre ekleyerek veya çıkararak paket kapasitesi kolayca ayarlanabiliyor

Tesla, yeni modeller için daha büyük format hücrelere geçse de, 18650 tabanlı araçlarının başarısı, tüketici batarya teknolojisinin otomotiv uygulamalarına ölçeklenebileceğini kanıtladı.

Elektrikli Bisikletler ve Kişisel Hareketlilik

Elektrikli bisikletler ve scooterlar, 18650 uygulamaları için başka bir önemli büyüme alanını temsil ediyor.

Tipik bir e-bisiklet batarya paketi, 36V veya 48V sistemler sağlamak üzere 40-60 18650 hücre içerir. Bu da sürücülere:

-

Tek şarjda 30-60 mil menzil

-

Makul ağırlık (çoğu paket 15 poundun altında)

-

Kolay şarj için çıkarılabilir bataryalar

-

Aynı üreticiden çeşitli kapasite seçenekleri

Vaping ve Yüksek Akım Uygulamaları

Vaping endüstrisi, yüksek performanslı 18650 bataryaların önemli bir tüketicisi haline geldi.

Vaping cihazları, bobinleri hızlıca ısıtmak için yüksek akım patlamalarını güvenli şekilde sağlayabilen bataryalara ihtiyaç duyar. Özellikle Sony VTC serisi gibi yüksek akım çeken 18650 hücreler, bu uygulamalar için özel olarak tasarlanmıştır.

Önemli Güvenlik Notu: Buharlaştırma uygulamaları uygun pil kullanımı ve saygın üreticilerden kaliteli hücreler gerektirir. Ucuz taklit piller yüksek akım uygulamalarında tehlikeli olabilir.

Endüstriyel ve Ticari Uygulamalar

Yedek Güç Sistemleri

Kesintisiz Güç Kaynağı (UPS) sistemleri giderek daha fazla yedek güç uygulamaları için 18650 teknolojisini kullanmaktadır.

Geleneksel kurşun-asit piller ağırdır, sınırlı döngü ömrüne sahiptir ve düzenli bakım gerektirir. 18650 tabanlı UPS sistemleri şunları sunar:

-

Daha yüksek enerji yoğunluğu (daha az alanda daha fazla çalışma süresi)

-

Daha uzun ömür (kurşun-asit için 3-5 yıl yerine 5-10 yıl)

-

Bakım gerektirmez

-

Sıcaklık ekstremlerinde daha iyi performans

Güneş Enerjisi Depolama

Ev güneş enerjisi kurulumları, konut batarya depolama talebini artırmakta ve 18650 hücreleri genellikle tercih edilen teknolojidir.

Örneğin, Tesla’nın Powerwall’ı, fazla güneş enerjisini daha sonra kullanmak üzere depolamak için binlerce 18650 hücre kullanır. Bu kurulum şunları sağlar:

-

13.5kWh kullanılabilir kapasite

-

Güneş panelleri ile sorunsuz entegrasyon

-

Enerji arbitrajı için şebeke bağlantısı özellikleri

-

Kesinti sırasında yedek güç

Robotik ve Otomasyon

Endüstriyel robotlar ve otomatik yönlendirilmiş araçlar (AGV’ler) giderek daha fazla hareketli güç için 18650 pil paketlerine güvenmektedir.

Standartlaştırılmış form faktörü, hızlıca değiştirilebilen veya şarj edilebilen modüler pil sistemleri tasarlamayı kolaylaştırır. Ayrıca, yüksek güç-ağırlık oranı, ağırlığı minimize ederken çalışma süresini maksimize etmesi gereken hareketli robotlar için çok önemlidir.

Tıbbi ve Güvenlik Ekipmanları

Taşınabilir Tıbbi Cihazlar

Taşınabilir oksijen konsantratörleri, uyku apnesi makineleri ve diğer tıbbi ekipmanlar genellikle mobil çalışma için 18650 piller kullanır.

Kaliteli 18650 hücrelerin güvenilirliği ve uzun döngü ömrü, pil arızasının seçenek olmadığı yaşam-kritik uygulamalar için idealdir.

Acil Durum ve Güvenlik Ekipmanları

Profesyonel acil durum aydınlatması, duman dedektörleri ve güvenlik iletişim cihazları sıklıkla 18650 teknolojisine dayanır.

Uzun raf ömrü, yüksek kapasite ve güvenilir performans kombinasyonu, pillerin aylarca kullanılmadan durabileceği ancak çağrıldığında kusursuz çalışması gereken uygulamalar için 18650'leri mükemmel kılar.

Gelişen ve Gelecekteki Uygulamalar

Şebeke Ölçekli Enerji Depolama

Bireysel 18650 hücreler küçük olmasına rağmen, şebeke ölçekli enerji depolaması için büyük batarya kurulumlarına entegre edilmektedir.

Bu sistemler, fazla yenilenebilir enerjiyi depolayarak ve pik talep dönemlerinde serbest bırakarak elektrik şebekelerini stabilize etmeye yardımcı olur.

Elektrikli Havacılık

Havacılık endüstrisi, küçük uçaklar için elektrikli tahrik sistemlerini araştırıyor ve 18650 hücreleri, kanıtlanmış güvenilirlikleri ve enerji yoğunlukları nedeniyle prototip sistemlerde sıklıkla kullanılır.

Uzay Uygulamaları

Küçük uydular ve uzay görevleri bazen 18650 piller kullanır çünkü güvenilirlikleri, standartlaştırmaları ve kapsamlı test geçmişleri vardır.

Güvenlik ve En İyi Uygulamalar

18650 piller genellikle doğru kullanıldığında güvenlidir, ancak yüksek enerji yoğunlukları saygı gösterilmesini gerektirir:

-

Kaliteli şarj cihazları kullanın lityum iyon piller için tasarlanmış

-

Fiziksel hasardan kaçının iç kısa devreye neden olabilecek

-

Uygun sıcaklıklarda saklayın (ideal olarak 50-70°F)

-

Aşırı deşarj etmeyin üretici spesifikasyonlarının altında

-

Doğru şekilde geri dönüştürün belirlenmiş pil geri dönüşüm merkezlerinde

18650 Teknolojisinin Geleceği

Daha yeni pil formatlarının piyasaya girmesine rağmen, 18650 hücreleri gelişmeye devam ediyor:

-

Daha yüksek kapasiteler: Modern hücreler 3.500mAh'yi aşıyor

-

Daha iyi güvenlik: Gelişmiş koruma devreleri ve termal stabilite

-

Daha hızlı şarj: Bazı hücreler güvenle 2C hızında şarj edilebilir

-

Daha düşük maliyetler: Ölçek ekonomileri fiyatları düşürmeye devam ediyor

Sonuç

Esneklik 18650 pil kullanımları teknoloji geliştikçe genişlemeye devam ediyor.

Çantanızdaki dizüstü bilgisayardan, girişinizdeki elektrikli araca kadar, bu standartlaştırılmış lityum iyon hücreleri taşınabilir, elektrikli dünyamızın görünmez omurgası haline geldi.

Günlük kullandığınız cihazları anlamak isteyen bir tüketici, yeni nesil taşınabilir ekipman tasarlayan bir mühendis veya yeni uygulamaları keşfeden bir girişimci olun, anlamak 18650 pil kullanımları modern dünyamızı şekillendiren en önemli teknolojilerden biri hakkında size içgörü sağlar.

Bir kablosuz matkap alırken, telefonunuzu power bank ile şarj ederken veya bir Tesla'nın geçerken, unutmayın: muhtemelen bunların hepsini mümkün kılan bir grup 18650 hücre var.