Pil Yeniliğinde Küresel Stratejik Ortağınız

Tedarikçiden Daha Fazla — Mühendislik Yoldaşınız

Geleceğinizi güçlendiren hassas mühendislikli lityum iyon pil sistemleri sunuyoruz

Güvene Dayalı, Yeniliğe İtici

Yerel bir fabrikadan küresel tanınan yüksek teknoloji şirketine

2012’den Beri Yolculuğumuz

Çin'in Dongguan şehrinde kurulan Nuranu Yenilenebilir Enerji, tek bir misyonla başladı: işletmeleri güvenilir, en son enerji çözümleriyle güçlendirmek. Son on yılda, geleneksel bir üretim tesisinden sertifikalı yüksek teknoloji şirketine dönüştük ve 50'den fazla ülkeye hizmet veriyoruz.

Bugün, mükemmelliği talep eden OEM üreticileri, distribütörler ve mühendislik ekipleri için güvenilir bir ortak olarak duruyoruz. Taahhüdümüz sadece pil teslim etmekle sınırlı değil — güven, yenilik ve uzun vadeli ortaklık sunuyoruz.

Vizyonumuz: Ürünlerinizin en yüksek performansla çalışmasını sağlayan güvenilir, sürdürülebilir enerji çözümleriyle geleceği güçlendirmek.

Başarınızı Güçlendiren Temel Yetkinlikler

Mükemmelliğin üç temel taşı

Özelleştirilmiş Ar-Ge Yetkinlikleri

- Hücre seçiminden BMS programlamasına kadar tam spektrum tasarım

- Uygulama özel pil mimarisi

- Hızlı prototipleme ve doğrulama

- Termal yönetim optimizasyonu

- Güvenlik öncelikli mühendislik yaklaşımı

Ölçeklenebilir Üretim

- Aylık 100.000+ birim üretim kapasitesi

- 24/7 otomatik üretim hatları

- ISO 9001 sertifikalı kalite sistemleri

- Acil talepler için esnek zamanlama

- Prototipten seri üretime sorunsuz geçiş

Kalite Güvencesi

- UN38.3 taşıma sertifikası

- CE, UL, IEC 62133 uyumlu

- 100% hat sonu testleri

- 98.5% kalite geçiş oranı

- Kapsamlı garanti programları

Her Hücrede Endüstri Standardı Güvenilirlik

Tutarlı mükemmeliyet sağlayan gelişmiş üretim altyapısı

En Son Teknoloji Üretim

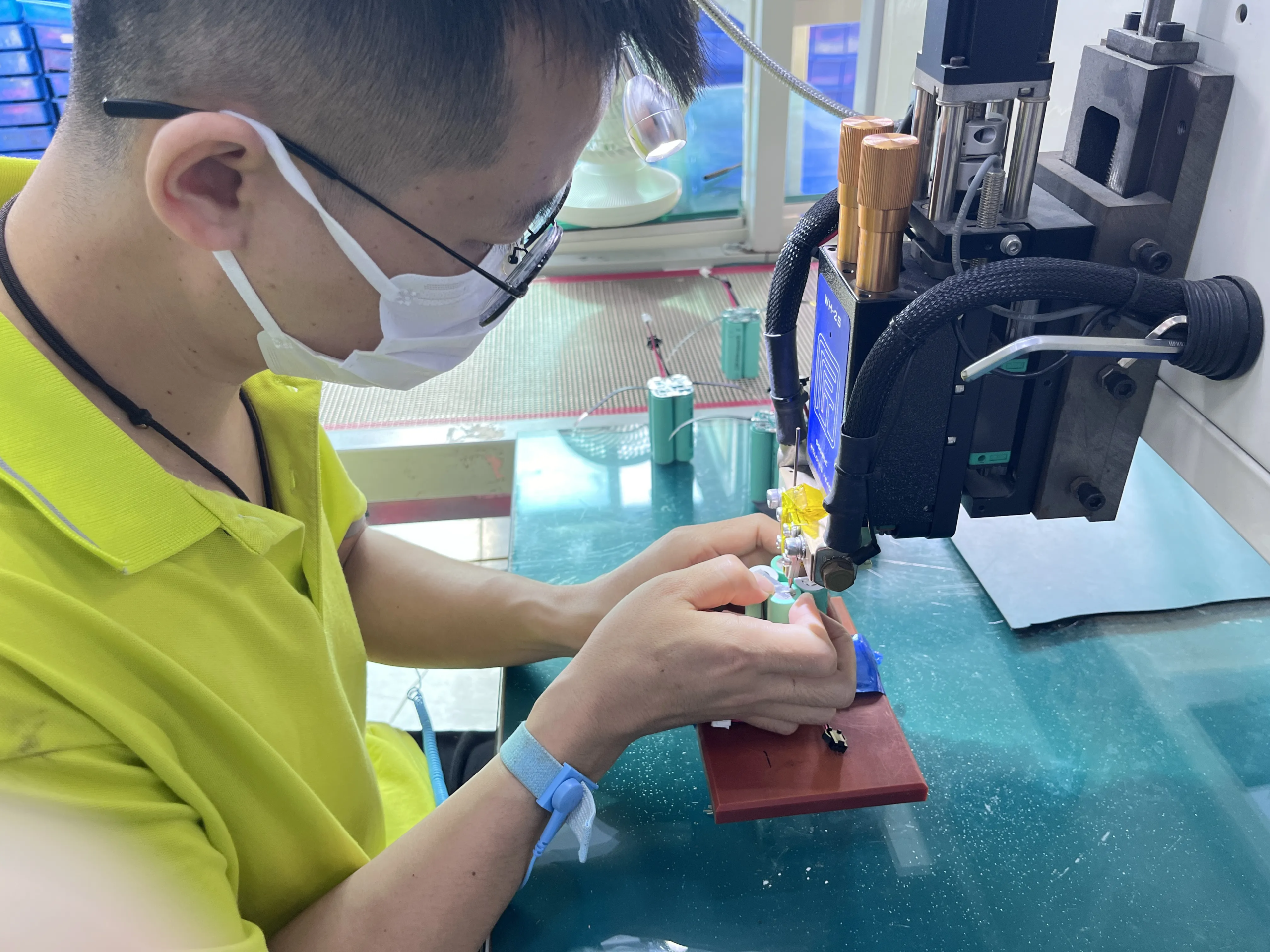

- Otomatik Nokta Kaynak Sistemleri: Günlük binlerce birimde tutarlı kalite ile hassas kaynak

- Gelişmiş Yaşlandırma Test Ekipmanları: Hızlandırılmış yaşam döngüsü testi, sevkiyat öncesi uzun vadeli güvenilirliği sağlar

- Temiz Oda Montajı: BMS ve hassas elektronik entegrasyonu için kontaminasyon içermeyen ortam

- Gerçek Zamanlı Kalite İzleme: Yapay Zeka destekli denetim sistemleri her üretim aşamasında kusurları tespit eder

- Çevresel Test Odaları: Aşırı sıcaklıklarda doğrulama (-40°C ile +85°C arasında)

- Otomatik Hücre Sıralama: Mükemmel uyum sağlayan hücreler ile en iyi performans ve dayanıklılık sağlar

Güvenilir Küresel Sertifikalar

Uluslararası standartlara uygun kapsamlı uyumluluk

UN38.3

Güvenli Taşıma Sertifikası

CE İşareti

Avrupa Uygunluk Belgesi

ELT Sertifikalı

Kuzey Amerika Güvenliği

FCC 62133

Pil Güvenliği Standartları

PSE

Kalite Yönetimi

Misyonumuz ve Temel Değerlerimiz

Her ortaklığı yönlendiren ilkeler

Müşteri Odaklı Ortaklık

Başarınız bizim ölçümümüzdür. Sadece ürün teslim etmiyoruz — mühendislik ekibinizin bir uzantısı oluyoruz, zaman çizelgenizi etkilemeden sorunları çözüyoruz.

Sonsuz Yenilikçilik

Sürekli Ar-Ge yatırımları, sektör trendlerinin önünde olmamızı sağlar. Yarınki batarya teknolojisini bugün ürünlerinize getiriyoruz, size rekabet avantajı sağlıyoruz.

Tavizsiz Kalite

Her batarya markanızın itibarını korur. Sıkı test protokollerimiz ve sertifikalarımız, müşterilerinizin güvenle kullanabileceği ürünler almasını sağlar.

Güvenliğin Neden Önemli Olduğunu Anlıyoruz

Her ürettiğimiz bataryanın, müşterilerinizin günlük ulaşımını sağladığı, çalışmalarını desteklediği veya yaşam tarzlarını sürdürebildiği bir ürünün parçası olduğunu biliyoruz. Bu sorumluluk, tasarımdan teslimata kadar her aşamada güvenlik, kalite ve güvenilirliğe olan takıntımızı besliyor.

Bir Sonraki İnovasyonunuza Güç Vermeye Hazır mısınız?

Nuranu'ya stratejik batarya ortağı olarak güvenen 500'den fazla üreticiye katılın

Hakkımızda

2012 yılında kurulan Nuranu, şarj edilebilir pil paketleri ürünleri ve aksesuarlarının geliştirilmesi, üretimi, pazarlanması ve servisi konusunda uzmanlaşmış bir yüksek teknoloji kuruluşudur.

Bize Ulaşın

- E-posta: info@nuranu.com

- Telefon numarası: +86-769-81010510

- Cep telefonu: +86-13823274651

- Adres: Oda 301, 2. Bina, No. 55, Shikeng Yolu, Hengli Kasabası, Dongguan, Guangdong Eyaleti, Çin

Nuranu WeChat