How to Connect 18650 Batteries Without Solder

Lithium-ion 18650 batteries are extremely useful for powering all kinds of electronics projects. However, properly connecting these batteries can be tricky, especially if you want to avoid soldering.

In this post, I’ll walk you through several methods for connecting 18650 battery cells without any soldering required.

Why Avoid Soldering 18650 Batteries?

Before we get into the details, you may be wondering why you’d want to avoid soldering 18650 battery connections in the first place. After all, soldering is a common way to create electrical connections.

There are a few reasons why soldering lithium-ion cells is not ideal:

- The heat can damage the batteries’ internal components if you’re not extremely careful. This can reduce battery life or even make the batteries unstable.

- Soldered connections may fail over time due to vibration or mechanical stress. This failure mode is accelerated at high discharge currents.

- It takes practice to quickly solder battery terminals without overheating the cell. Beginners often end up damaging cells while learning.

- In many jurisdictions, devices with soldered lithium-ion battery packs require expensive UL safety certifications. Avoiding solder simplifies the certification process.

So while it’s certainly possible to safely solder 18650 batteries if you really know what you’re doing, avoiding solder altogether makes life easier.

Fortunately, there are several good alternatives for electrically connecting these batteries.

How to Connect 18650 Batteries Without Solder

Method 1: Using an 18650 Battery Holder

The easiest no-solder method is to use an off-the-shelf 18650 battery holder.

These plastic holders securely hold individual 18650 cells, while also providing electrical contacts to their terminals. Multiple holders can be combined to create battery packs of different voltages and capacities.

Here are some of the advantages of using battery holders:

- Super quick and easy to assemble – no tools required

- Safer than DIY methods for novice users

- Readily accommodate replacing dead cells down the road

- Protect cells from vibration and shock loads

- Components widely available at low cost

However, 18650 holders do have some limitations:

- Contacts only rate for relatively low discharge currents (i.e. 10+ amps max)

- Large form factor – a 12-cell pack will be pretty bulky

As long as your project draws modest currents, these simple plastic holders provide a great option for lithium battery packs with no soldering required.

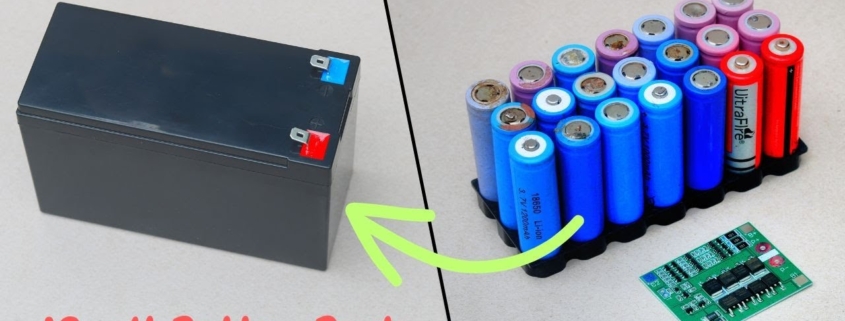

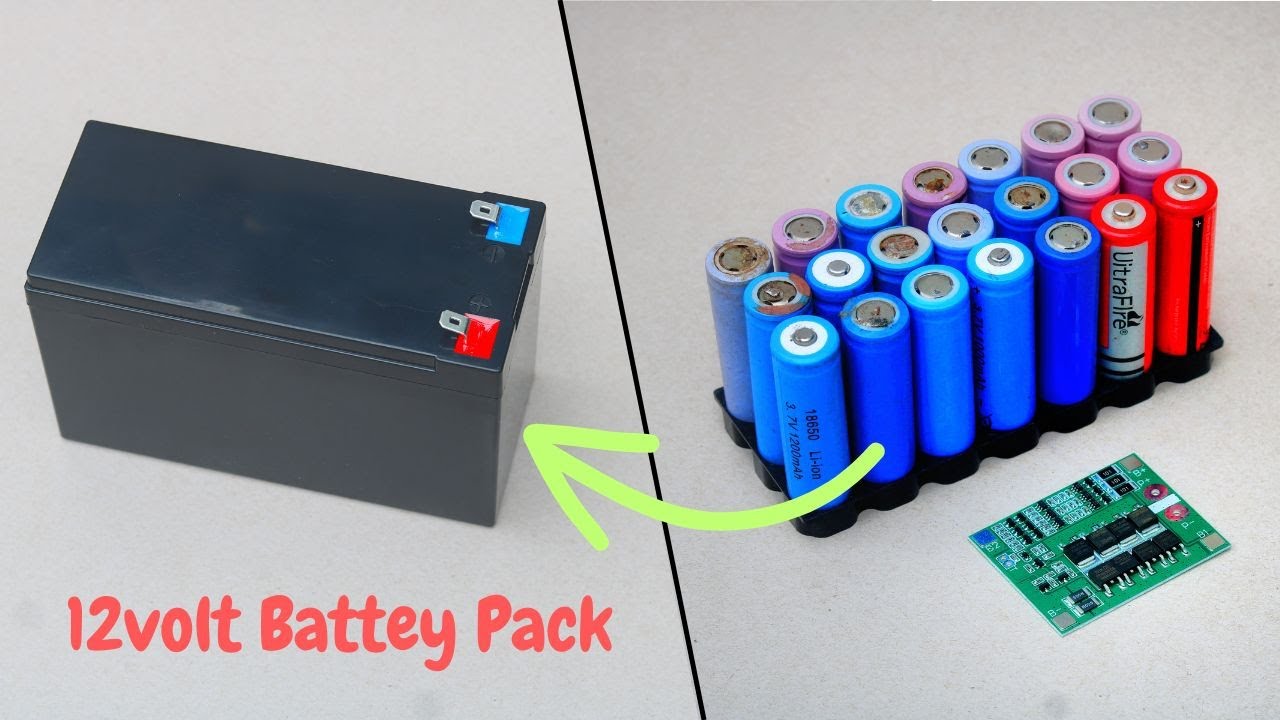

I used this basic approach to create a small 12V lithium power bank. Worked like a charm!

Method 2: Nickel Strips and Spot Welding

For moderate to high-current battery packs, nickel strips often provide the best performance and reliability.

Rather than soldering, individual nickel strips are spot welded to connect cells in series and parallel. This creates a rigid mechanical bond while also forming a low-resistance electrical connection.

Constructing battery packs from raw 18650 cells using nickel strips delivers:

- Maximum electrical and mechanical integrity

- High peak discharge capabilities

- Compact form factor (for a given energy capacity)

- Flexible configurations and cell counts

Unfortunately, DIY spot welding solutions remain expensive, complex, and potentially dangerous for novice users. In other words, not exactly easy no-solder options.

Method 3: PCB Spot Welder Adapter Boards

Lately, some small companies have developed adapter PCBs that enable DIYers to spot weld lithium cells without building a spot welder.

These adapter boards have pre-tinned heavy copper pads spaced to precisely match 18650 cell dimensions.

To assemble a battery, you:

- Arrange layered rows of bare lithium cells on the PCB

- Use a conventional PCB hand soldering iron to “spot weld” nickel strips onto the copper pads

- Solder strips between alternate rows to connect cells in series & parallel

In essence, these adapter boards transform an inexpensive 40W soldering iron into a capable tab welder!

The advantages of this approach over old-school spot welding include:

- Far lower equipment cost

- Simple enough for non-technical builders

- Consistent, reliable electrical connections

- No battery holder = compact form factor

- Much faster assembly process

For low-moderate production volumes, using PCB battery welding adapters checks all the boxes for no-solder 18650 battery packs!

Still Stumped on Connecting 18650s Sans Solder?

Hopefully the above overview gave you some ideas on securely connecting 18650 lithium-ion cells without any soldering or welding equipment required.

As you saw, both off-the-shelf battery holders and newcomer PCB spot welding adapters provide viable no-solder methods for 18650 projects.

The approach that will work best depends mainly on your target discharge current, complexity tolerance, and overall budget.

If you’re STILL looking for tips on putting together18650 packs without soldering, I’d be happy to help! Just drop me a comment below.

Let me know if this quick guide helped explain no-solder 18650 connection options. Until next time, keep making awesome stuff!