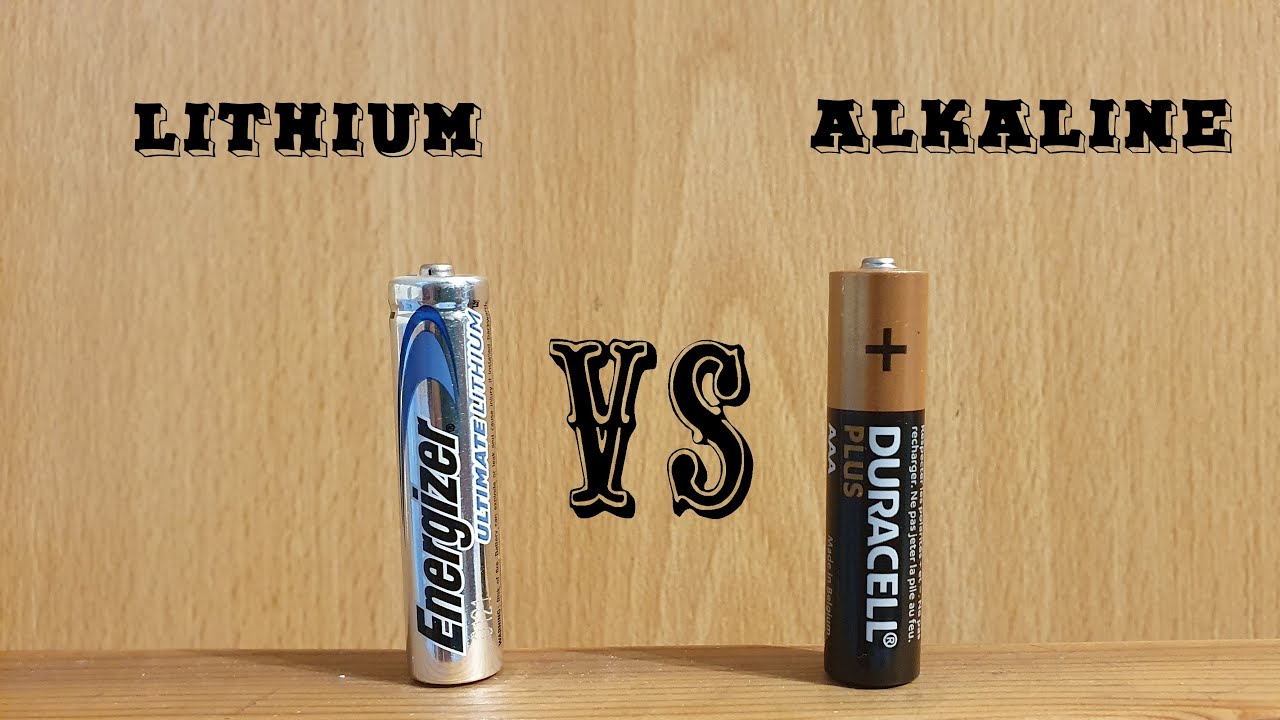

What is the Difference Between Alkaline and Lithium Batteries?

What is the difference between alkaline and lithium batteries? It’s a question I get asked all the time. And for good reason.

Choosing the wrong battery for your device can mean the difference between months of reliable performance and constantly replacing dead batteries.

Here’s the thing: alkaline and lithium batteries might look similar on the outside, but they’re completely different beasts under the hood.

In this guide, as a professional lithium battery pack manufacturer, I’m going to break down everything you need to know about these two battery types. By the end, you’ll know exactly which one to choose for any situation.

Let’s dive in.

The Chemistry Behind the Power

Before we get into the practical differences, let me explain what’s actually happening inside these batteries.

Alkaline Battery Chemistry

Alkaline batteries use a zinc anode and manganese dioxide cathode, with potassium hydroxide as the electrolyte.

Here’s how it works: the zinc gets oxidized at the negative terminal while the manganese dioxide gets reduced at the positive terminal. The potassium hydroxide electrolyte facilitates this reaction.

The result? A steady 1.5 volts per cell.

Lithium Battery Chemistry

Lithium batteries are more complex. Primary lithium batteries typically use lithium metal or lithium compounds as the anode, paired with various cathode materials like iron phosphate or cobalt oxide.

The electrolyte is non-aqueous (meaning no water), which allows lithium ions to move between electrodes.

And here’s where it gets interesting: lithium batteries can deliver anywhere from 1.5V to 3.7V per cell, depending on the specific chemistry.

Difference Between Alkaline and Lithium Batteries

Energy Density: Where Lithium Dominates

One of the biggest differences between these battery types is energy density.

Energy density is how much power a battery can store relative to its size and weight.

And lithium absolutely crushes alkaline in this department.

Here are the numbers:

Alkaline batteries: 80-100 Wh/kg

Lithium batteries: 200-300 Wh/kg

That means lithium batteries can store 3-6 times more energy in the same space.

Real-World Impact

What does this mean for you?

Let’s say you’re using a digital camera. An alkaline AA battery might give you 100-150 shots. But a lithium AA? You’re looking at 600-800 shots under the same conditions.

That’s a massive difference.

Plus, lithium batteries are significantly lighter. If you’re carrying outdoor gear or professional equipment, every ounce matters.

Performance Characteristics: Why Voltage Matters

Here’s where things get really interesting.

Voltage Output Patterns

Alkaline batteries have what I call a “gradual decline” voltage curve. They start at 1.5V but slowly drop throughout their life cycle.

Your device performance gradually gets worse as the battery drains.

Lithium batteries? Completely different story.

They maintain consistent voltage output almost until they’re completely dead. This means your devices get consistent power throughout the battery’s entire life.

High-Drain Performance

This is where alkaline batteries really struggle.

In high-drain devices (think digital cameras, LED flashlights, or power tools), alkaline batteries can lose up to 75% of their theoretical capacity.

Why? Higher current draw increases internal resistance, which reduces available power.

Lithium batteries have much lower internal resistance. They excel in high-drain applications and actually perform better under load.

Temperature Performance: The Cold Weather Champion

If you’ve ever used alkaline batteries in cold weather, you know they basically stop working.

Here’s why:

At 0°F (-18°C), alkaline batteries lose about 75% of their capacity. The chemical reactions slow down dramatically in cold temperatures.

Lithium batteries? They keep chugging along.

They maintain consistent performance from -40°F to 140°F (-40°C to 60°C). That’s why they’re essential for:

Outdoor equipment

Emergency devices

Winter sports gear

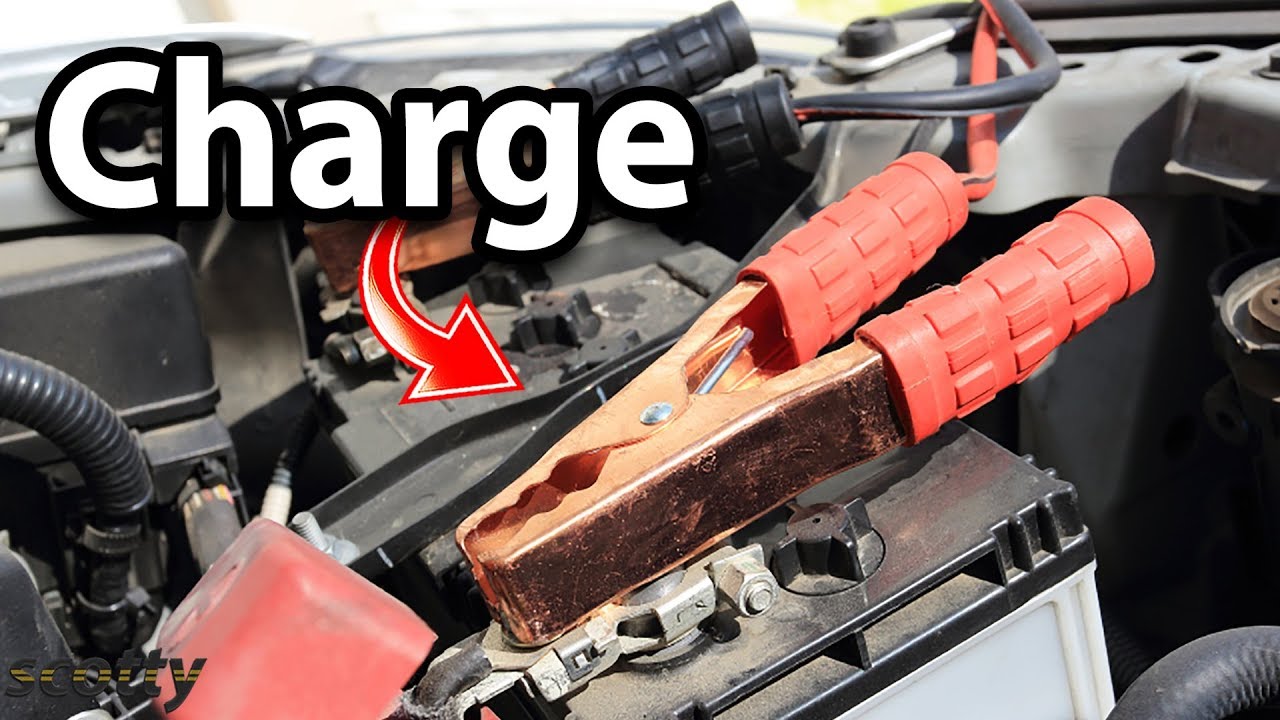

Automotive applications

Shelf Life: The Long-Term Storage Winner

This one’s not even close.

Alkaline batteries typically maintain 80% of their capacity for 5-7 years when stored properly. They lose about 5% of their energy per year.

Lithium batteries can retain 90% of their capacity for 10-15 years or more.

For emergency preparedness or infrequently used devices, lithium is the clear winner.

Self-Discharge Rates

Here are the annual self-discharge rates:

Alkaline: 2-3% per year

Lithium: Less than 1% per year

That’s why lithium batteries are perfect for smoke detectors, emergency flashlights, and backup devices.

Cost Analysis: Initial vs. Long-Term Value

Let’s talk money.

Alkaline batteries are definitely cheaper upfront. You can usually get alkaline AAs for $0.50-$1.00 each.

Lithium batteries? Expect to pay $2.00-$5.00 per battery.

But here’s the thing: you need to look at cost per hour of use, not just upfront cost.

Real Example

Let’s say you need batteries for a high-drain device that runs 4 hours per day:

Alkaline option:

Cost: $1.00 per battery

Lifespan: 25 hours

Daily replacement cost: $0.16

Lithium option:

Cost: $3.00 per battery

Lifespan: 200 hours

Daily replacement cost: $0.06

The lithium battery is actually 62% cheaper to operate long-term.

For low-drain devices like wall clocks or TV remotes, alkaline makes more sense. But for anything that uses significant power, lithium pays for itself quickly.

Safety and Environmental Considerations

Both battery types are generally safe when used properly, but there are some important differences.

Alkaline Battery Safety

The main issue with alkaline batteries is leakage. Over time (especially when fully discharged), they can leak potassium hydroxide.

This white, crusty substance can damage your devices. While not extremely dangerous, it can cause skin irritation.

Lithium Battery Safety

Lithium batteries are less prone to leakage due to their stable chemistry.

However, they can be sensitive to:

Extreme temperatures

Physical damage

Overcharging (for rechargeable types)

When mishandled, lithium batteries can overheat or even catch fire. But when used according to manufacturer guidelines, this risk is extremely minimal (about 1 in 10 million).

Environmental Impact

Modern alkaline batteries don’t contain mercury or other highly toxic materials. But they’re primarily disposable and contribute to electronic waste.

Lithium batteries are more environmentally friendly in several ways:

They last much longer, reducing replacement frequency

Many are rechargeable (for thousands of cycles)

They contain valuable materials that are highly recyclable

Over 90% of lithium battery materials can be recovered and reused

When to Choose Alkaline Batteries

Despite lithium’s advantages, alkaline batteries still make sense in certain situations:

Low-Drain Devices

Wall clocks

TV remotes

Basic flashlights

Small toys

Wireless keyboards and mice

Budget-Conscious Applications

When upfront cost is the primary concern and you don’t need maximum performance.

Infrequent Use

For devices you rarely use where the battery might sit for months without being needed.

When to Choose Lithium Batteries

Lithium batteries are the better choice for:

High-Drain Devices

Digital cameras

GPS units

LED flashlights

Wireless microphones

Power tools

Extreme Conditions

Outdoor equipment

Cold weather applications

Hot climate devices

Emergency preparedness

Professional Applications

Where consistent performance and reliability are critical.

Long-Term Storage

Smoke detectors

Emergency radios

Backup equipment

Podsumowanie

What is the difference between alkaline and lithium batteries? The differences are significant and impact everything from performance to cost-effectiveness.

Here’s my recommendation:

Choose alkaline for: Low-drain devices, budget applications, and situations where upfront cost matters most.

Choose lithium for: High-drain devices, extreme temperatures, professional equipment, and long-term storage applications.

In 2025, with lithium battery prices continuing to drop and performance improving, they’re becoming the go-to choice for more and more applications.

The key is matching the battery type to your specific needs. Consider factors like:

Device power requirements

Operating environment

Usage frequency

Total cost of ownership

Performance requirements

Get this right, and you’ll save money while getting better performance from your devices.

Understanding what is the difference between alkaline and lithium batteries isn’t just about chemistry – it’s about making smart choices that improve your daily life and save you money in the long run.