OEM-Ready 26650 LiFePO4 Battery Pack Solutions for Professional Projects

Reliable 26650 rechargeable battery packs in 60V, 12V, and 11.1V configurations

- Stable LiFePO4 chemistry for industrial and energy applications

- Multiple capacity options: 6Ah / 18Ah / 40Ah / 60Ah

- Custom BMS, connectors, and enclosure options for OEM integration

- Fast engineering support: drawings, wiring, and pack validation

Why Our 26650 Battery Packs

10+ Years of 26650 Pack Manufacturing Experience

We specialize in 26650 battery pack production and LiFePO4 technology, providing stable, scalable power solutions for OEM customers worldwide.

End-to-End Customization for OEM Integration

From pack configuration and BMS protection to connector selection and enclosure design, we offer one-stop customization. Supported platforms include 12V, 11.1V, and 60V, with capacities from 6Ah up to 60Ah.

Strict Quality Control and Consistency

Every 26650 cell is screened for voltage, capacity, and internal resistance. Pack-level matching targets ≤2% consistency. Aging tests are performed prior to assembly, and we support compliance documentation such as UN38.3 and MSDS where required.

Fast Engineering Response

We provide complete technical documentation (drawings, wiring diagrams, BMS parameters) and support the full process from samples to pilot builds to mass production. Engineering support is available to help accelerate validation and design changes.

Choose Your 26650 Battery Pack

5 popular SKUs to cover common OEM use cases

12V 6Ah 26650 LiFePO4 Battery Pack

Voltage: 12V (4S configuration)

Capacity: 6Ah

Energy: 76.8Wh

Ideal for portable devices, compact UPS, and OEM equipment. Lightweight and space-efficient for tight enclosures.

12V 18Ah 26650 LiFePO4 Battery Pack

Voltage: 12V (4S configuration)

Capacity: 18Ah

Energy: 230.4Wh

For monitoring systems, portable instruments, and backup modules. A balanced mid-capacity solution.

12V 40Ah 26650 LiFePO4 Battery Pack

Voltage: 12V (4S configuration)

Capacity: 40Ah

Energy: 512Wh

Commonly used for off-grid modules, industrial power units, and extended backup runtimes.

11.1V 6Ah 26650 LiFePO4 Battery Pack

Voltage: 11.1V (3S configuration)

Capacity: 6Ah

Energy: 66.6Wh

Designed for compact systems using a 3S voltage platform. Fits professional devices that require 11.1V operation.

60V 20Ah 26650 LiFePO4 Battery Pack

Voltage: 60V (16S configuration)

Capacity: 20Ah

Energy: 1200Wh

High-voltage, high-energy solution for power tools, industrial equipment, and applications requiring higher output power.

Customization Options (All Models)

Flexible OEM Customization to Match Your Requirements

Every OEM program has its own constraints. We offer flexible options so your 26650 battery pack fits your electrical, mechanical, and compliance requirements.

Connector Options

Standard or custom connectors (XT, DC barrel, Anderson, etc.) to match your device interface

BMS Protection

Integrated BMS (overcharge/over-discharge/overcurrent/short-circuit). Current limits, temperature protection, and communication can be tailored.

Enclosure & Packaging

PVC wrap, ABS housing, or metal enclosure with optional protection levels

Cable & Harness

Custom cable length and gauge; optional harness, fuse, and switch integration

Labeling & Branding

Custom labels, packaging, and traceability options to support your brand

Pilot Build Support

Support from sample validation to pilot production to mass production to reduce program risk

Why Choose a 26650 Battery Pack for Your OEM Program?

Compared with smaller cylindrical cells, the 26650 format offers higher single-cell capacity and can reduce pack complexity in certain designs. For B2B buyers, the value is not only capacity—but predictable performance, stability, and supply reliability.

Key Benefits for B2B Buyers

Consistent Cell Matching

Cells are matched and screened (aging, IR sorting, capacity checks) to help keep in-pack consistency at ≤2%, improving overall pack life.

Lower Integration Risk

Verified pack structure, wiring design, and BMS protection logic—plus full technical documentation—can shorten your validation cycle and reduce engineering risk.

Scalable Supply Capability

We support the full ramp from samples to pilot runs to mass production. Production planning and capacity can be aligned to mid-to-large OEM programs for supply stability.

Engineering-Friendly Documentation

We provide CAD drawings, wiring diagrams, and BMS parameter sheets, with responsive technical support for design changes and troubleshooting.

Core Specs & Dimensions

26650 cell dimensions and pack-level specifications

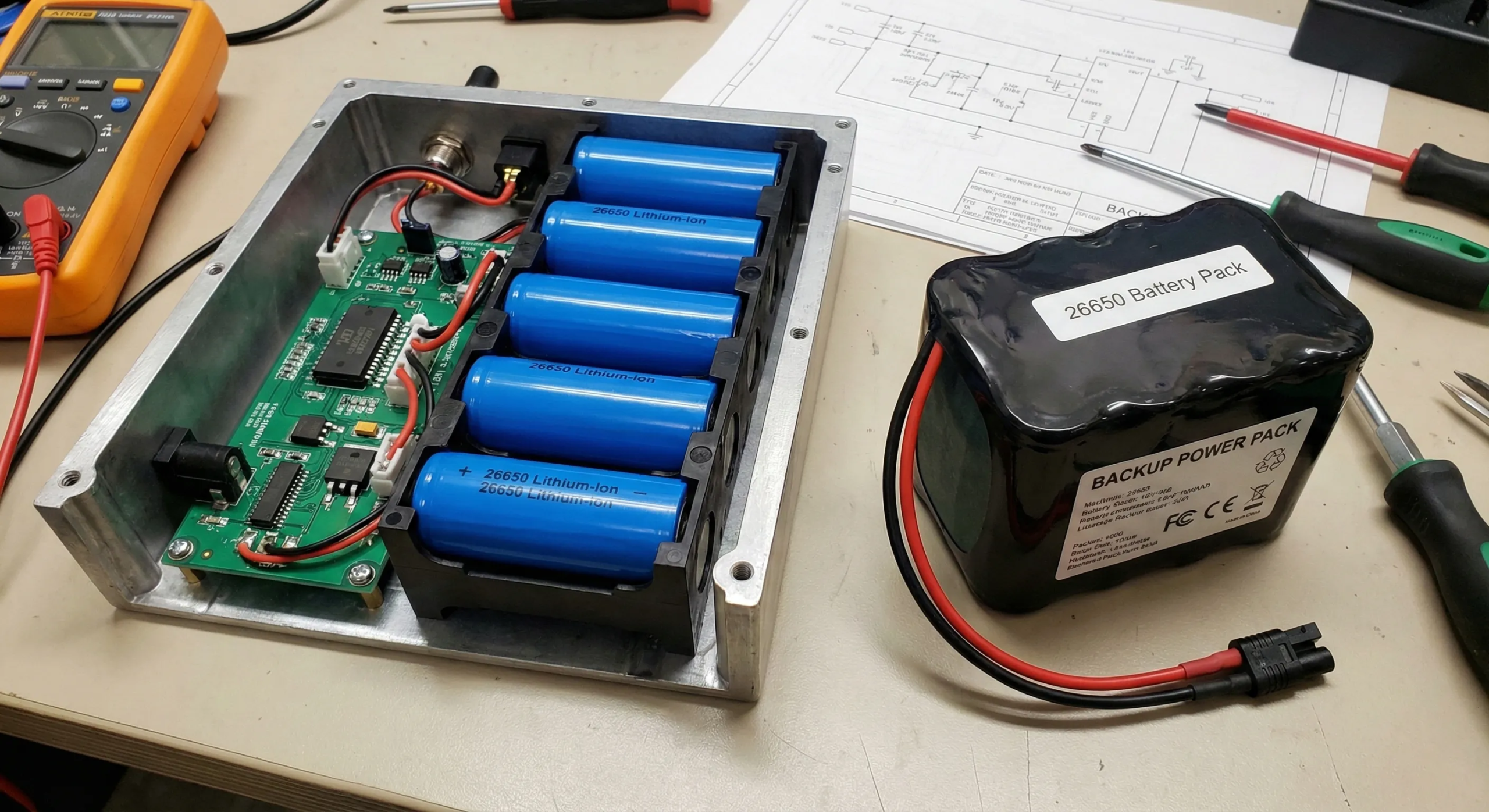

26650 Cell Basics

Format definition: “26650” typically indicates a cylindrical cell about 26mm in diameter and 65mm in length (tolerances vary by manufacturer and design).

Typical Pack-Level Specifications

| Nominal Voltage | 12V class (4S), 11.1V class (3S), 60V class (16S) |

| Capacity Options | 6Ah / 18Ah / 40Ah / 60Ah |

| Protection | BMS protection for safe charge/discharge (overcharge/over-discharge/overcurrent/short-circuit) |

| Discharge Capability | Customizable continuous/peak current; up to 3C discharge depending on design |

| Operating Temperature | Charge: 0°C to 45°C / Discharge: -20°C to 60°C |

| Cycle Life | >2000 cycles @ 80% DoD (LiFePO4 chemistry) |

Keyword coverage: 26650 battery size | 26650 battery specs | 26650 battery pack configuration

26650 vs 21700 vs 18650 vs 32650: Cell Format Comparison

Buyers often compare cylindrical formats to balance size, runtime, and pack design complexity

| Cell Format | Size (Diameter × Length) | Typical Capacity | Common Applications |

|---|---|---|---|

| 18650 | 18mm × 65mm | 2.5–3.5Ah | Laptops, flashlights, compact battery packs |

| 21700 | 21mm × 70mm | 4.0–5.0Ah | EVs, power tools, energy storage |

| 26650 | 26mm × 65mm | 3.0–6.0Ah | Industrial devices, UPS, mid-to-large packs |

| 32650 | 32mm × 65mm | 5.0–6.5Ah | Higher-capacity storage, backup power, off-grid systems |

Selection Tips

- Space-first: 18650 (smallest footprint)

- Balanced design: 26650 or 21700

- Maximum capacity per cell: 32650

- Value for mid-capacity packs: 26650 often offers strong cost/performance

Engineering note: Cell format selection should consider voltage platform, target capacity, discharge requirements, and enclosure space. Our engineering team can evaluate the best option for your application.

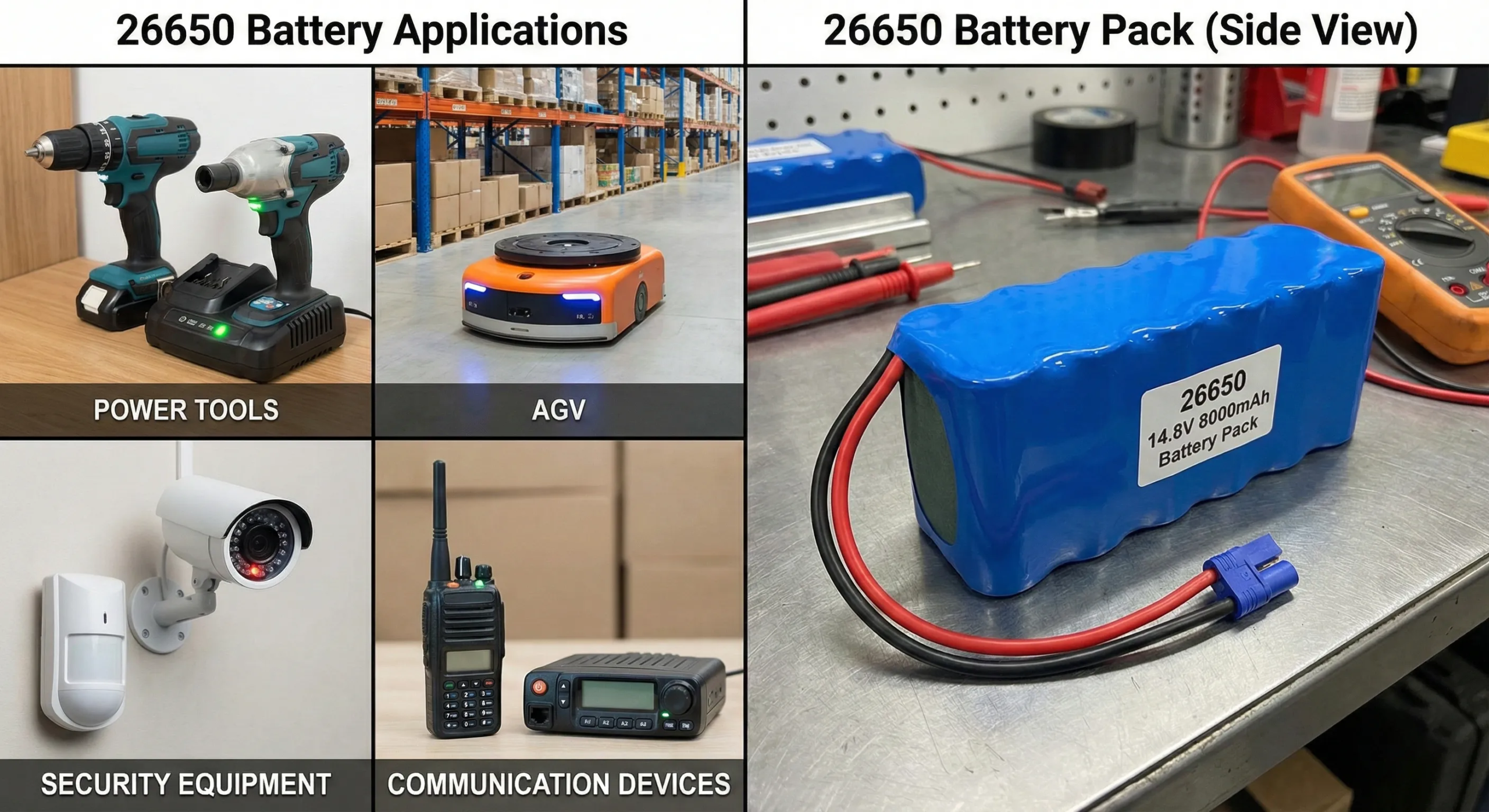

Applications for 26650 Lithium Battery Packs

Designed for professional integration where stability and predictable performance matter

Industrial Monitoring & Sensors

Long-life power for remote monitoring stations, environmental sensors, and IoT devices—supporting continuous data capture.

Backup Power Modules (UPS / Emergency Power)

For small UPS systems, emergency lighting, and telecom backup—reliable support during mains outages.

Portable Equipment & Instruments

Stable power for portable medical devices, measurement instruments, and handheld tools where reliability is critical.

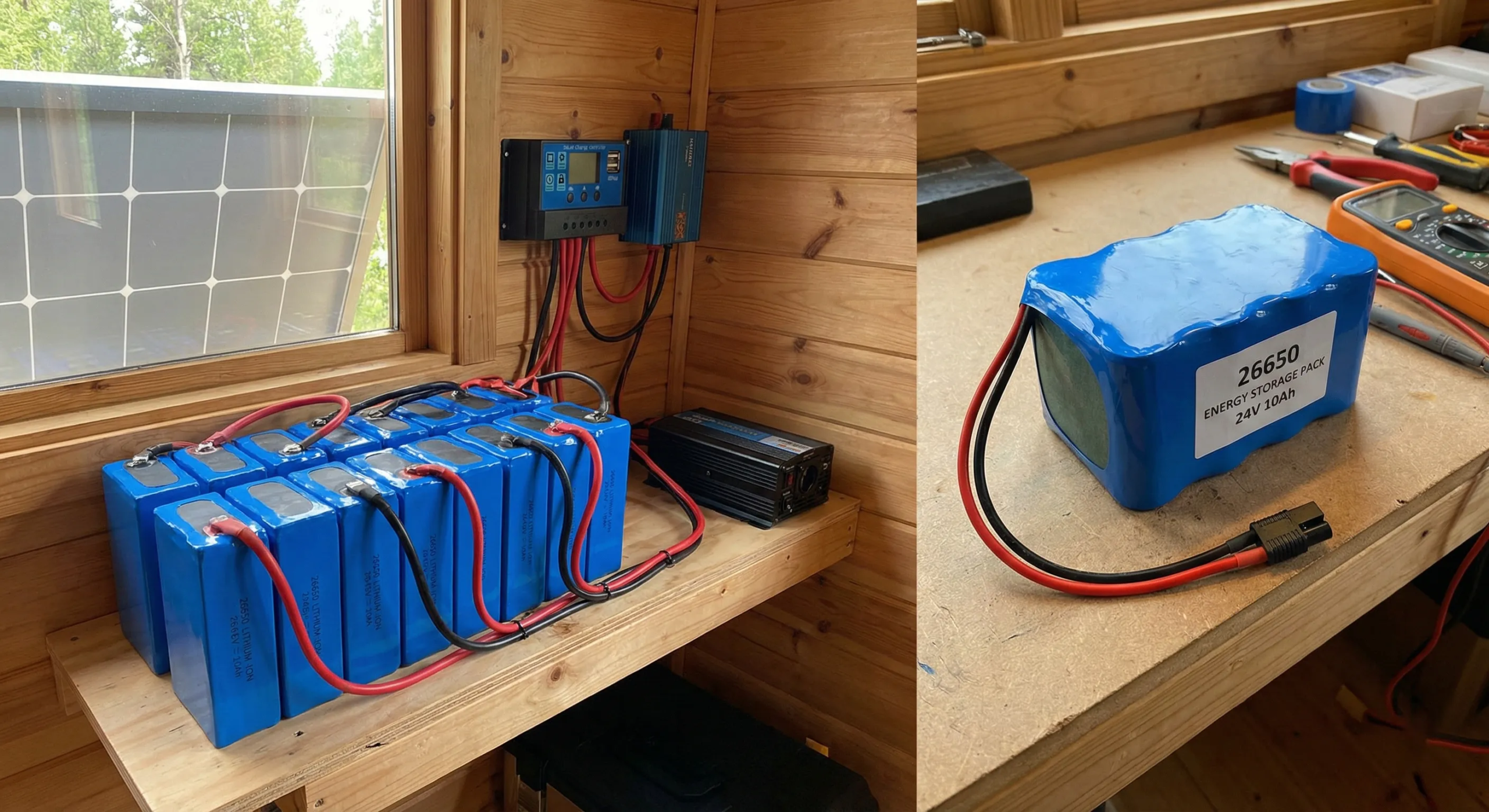

Off-Grid Modules & Small Energy Storage

For solar off-grid systems, home backup modules, and mobile power applications—efficient energy storage and delivery.

OEM Equipment Requiring Standard Voltage Platforms

Standardized power modules for industrial equipment, automation systems, and robotics—simplifying your product design workflow.

Additional Professional Use Cases

Power tools, AGVs, security devices, and telecom equipment—showcasing the flexibility of 26650 rechargeable battery packs.

Keywords: 26650 lithium battery | 26650 rechargeable battery | 26650 battery pack applications

26650 Battery Chargers & Charging Guidelines

For LiFePO4 packs, use a charger designed for LiFePO4 charge profiles (correct voltage and termination logic). If you search “26650 battery charger,” make sure you select based on chemistry and pack voltage—not the 26650 size alone.

Charging Essentials for 26650 LiFePO4 Packs

Select the Correct Charger Chemistry

LiFePO4 and Li-ion chargers are not interchangeable. LiFePO4 cells charge to 3.65V/cell, while Li-ion charges to 4.2V/cell. Using the wrong charger can damage the battery and create safety risks.

Match Charger Voltage to Pack Voltage

• 12V (4S) pack: use a 14.6V LiFePO4 charger

• 11.1V (3S) pack: use a 10.95V LiFePO4 charger

• 60V (16S) pack: use a 58.4V LiFePO4 charger

Recommended Charge Current by Capacity

• 6Ah pack: 1–3A recommended

• 18Ah pack: 3–9A recommended

• 40Ah pack: 8–20A recommended

(Standard: 0.2–0.5C / Fast: up to 1C depending on design)

Need a “Battery + Charger” Bundle for Your OEM Program?

We can recommend compatible chargers or provide bundled solutions to keep your charging system safe, consistent, and easy to deploy.

Keywords covered: 26650 battery charger | 26650 charging | battery and charger bundle | dedicated 26650 charger

Quality Control & Compliance Support

Quality systems and documentation that help overseas customers buy with confidence

Incoming Inspection & Batch Consistency Control

Cells undergo incoming inspection including open-circuit voltage, capacity, and internal resistance checks. Batch consistency targets within ±2% to support stable pack performance.

Pre-Assembly Aging Tests & IR/Voltage Sorting

Cells are aged prior to pack assembly to screen early failures. IR and voltage sorting helps keep cells within a tighter matching window for better reliability.

Functional Testing: Charge/Discharge & Protection Verification

Each pack is tested prior to shipment, including charge/discharge checks and BMS protection functions (overcharge/over-discharge/overcurrent/short-circuit/temperature).

Shipping Compliance Documents (Program-Based)

We can support documents such as UN38.3 test reports, MSDS, and declarations of conformity for air or sea freight, depending on your destination and program requirements.

FAQ

Clear answers for common technical and sourcing questions

What is a 26650 battery?

A 26650 battery is a cylindrical cell format. “26” refers to ~26mm diameter and “65” refers to ~65mm length (the final “0” indicates a cylindrical shape). In B2B projects, 26650 cells are commonly assembled into 26650 battery packs to deliver stable power. Compared with 18650, 26650 offers higher capacity per cell and is often used in mid-to-large battery packs.

Are these 26650 lithium-ion battery packs?

These are 26650 LiFePO4 (lithium iron phosphate) battery packs. Some buyers use terms like “26650 lithium ion battery” or “26650 lithium battery” as a general label for rechargeable lithium batteries. Important: Please confirm the chemistry before selecting a charger. LiFePO4 and Li-ion have different charge voltages and are not charger-compatible.

How do I choose a 26650 battery charger?

Choosing a 26650 battery charger depends on three factors:

1. Chemistry: Use a LiFePO4 charger (3.65V per cell termination)

2. Pack voltage: Select by series count (4S=14.6V, 3S=10.95V, 16S=58.4V)

3. Charge current: Typically 0.2–1C (for a 6Ah pack, a 1–6A charger is common)

We can recommend compatible chargers for each model to avoid selection errors.

Which is better: 26650 or 18650 rechargeable batteries?

The choice between 26650 vs 18650 depends on your design priorities:

Why choose 26650: higher capacity per cell, fewer cells for the same energy (simpler pack/BMS), well-suited for mid-to-large packs

Why choose 18650: smaller size, broader supply ecosystem, often lower unit cost

We can evaluate both options based on enclosure constraints, capacity targets, and cost goals.

What is the MOQ for 26650 battery packs?

We support flexible OEM ordering stages:

• Samples: 1–10 packs (functional and compatibility validation)

• Pilot run: 50–500 packs (design and quality verification)

• Mass production: 1,000+ packs (best unit pricing)

For long-term programs, we can discuss more flexible MOQs and stocking plans.

What is the cycle life of 26650 LiFePO4 battery packs?

Typical cycle life for our 26650 LiFePO4 battery packs:

• Standard: 2,000+ cycles @ 80% DoD

• Real-world: 4,000–5,000 cycles at ~50% DoD (application dependent)

• Service life: often 5–10 years in many use cases (depending on temperature, current, and DoD)

LiFePO4 typically provides a longer cycle life than conventional Li-ion chemistries, lowering total cost of ownership.

Do you provide engineering support and after-sales service?

Yes. We support OEM customers throughout the project lifecycle:

• Design: CAD drawings, wiring diagrams, BMS parameter sheets

• Validation: test support and troubleshooting

• Production: manufacturing coordination and traceability

• After-sales: warranty support and technical assistance

Typical response time is within 24 hours for technical questions.

Can I buy the battery pack and charger together?

Yes. We offer battery + charger bundles for OEM programs:

• Standard bundle: battery pack + matched charger + cable set

• Custom bundle: charger and cabling tailored to your device connector

• Volume pricing: bundle purchases may qualify for better pricing

Bundling helps ensure charger compatibility and reduces selection risk.

Ready to Power Your Next Product?

Let’s discuss your application requirements and explore how our battery solutions can accelerate your time to market.

- Email: info@nuranu.com

- Phone: +86 13823274651

- Add: Room 301, 2nd Building, No. 55, Shikeng Road, Hengli Town, Dongguan, Guangdong, China

About Us

Founded in 2012, Nuranu is a high-tech enterprise specializing in developing, manufacturing, marketing and serving of rechargeable battery packs products and accessories.

Contact Us

- E-mail: info@nuranu.com

- Phone: +86-769-81010510

- Mobile: +86-13823274651

- Address: Room 301, 2nd Building, No. 55, Shikeng Road, Hengli Town, Dongguan, Guangdong Province, China

Nuranu Wechat