คู่มืออัปเกรดแบตเตอรี่ลิเธียมสำหรับรถกอล์ฟปี 2025 ฉบับสมบูรณ์

แบตเตอรี่ลิเธียมสำหรับรถกอล์ฟ การอัปเกรดกำลังเป็นที่นิยมอย่างมากในตอนนี้ และเป็นเพราะเหตุผลที่ดี

เมื่อไม่นานมานี้ฉันได้ช่วยเพื่อนเปลี่ยนจากแบตเตอรี่ตะกั่วกรดเป็นลิเธียม ความแตกต่าง? เห็นได้ชัดเจนมาก

รถของเขาจากที่เคยลำบากขึ้นเนินก็กลายเป็นขับง่ายราวกับบนพื้นราบ นอกจากนี้ เขายังไม่แตะต้องเครื่องมือบำรุงรักษาแบตเตอรี่เลยเป็นเวลา 6 เดือน

นี่คือเรื่อง:

เจ้าของรถกอล์ฟส่วนใหญ่มักไม่รู้ว่าพวกเขากำลังปล่อยประสิทธิภาพที่ดีออกไปด้วยแบตเตอรี่แบบเก่า

ดังนั้นในคู่มือนี้ ในฐานะผู้เชี่ยวชาญ ผู้ผลิตชุดแบตเตอรี่ลิเธียมฉันจะแสดงให้คุณเห็นอย่างชัดเจนว่าทำไมแบตเตอรี่ลิเธียมถึงเหนือกว่าแบตเตอรี่ตะกั่วกรด และวิธีเลือกแบตเตอรี่ที่เหมาะสมที่สุดสำหรับรถของคุณ

มาเริ่มกันเลย

ทำไมแบตเตอรี่ลิเธียมถึงครองตลาดรถกอล์ฟ

นี่คือสถิติที่ทำให้ฉันประหลาดใจ:

ยอดขายแบตเตอรี่ลิเธียมสำหรับรถกอล์ฟพุ่งขึ้น 471 เท่าในปีที่ผ่านมา และคาดว่าจะเพิ่มเป็นสองเท่าภายในปี 2027

ทำไมถึงมีการเปลี่ยนแปลงครั้งใหญ่ขนาดนี้?

ง่ายมาก: แบตเตอรี่โ phosphates เหล็ก (LiFePO4) แก้ปัญหาเกือบทุกอย่างที่แบตเตอรี่ตะกั่วกรดมี

ข้อได้เปรียบด้านน้ำหนักเปลี่ยนทุกอย่าง

แบตเตอรี่ตะกั่วกรดมีน้ำหนักมาก

ประมาณ 300-400 ปอนด์ สำหรับระบบ 48V ทั่วไป

ลิเธียม? ลองประมาณ 90-120 ปอนด์

นั่นคือการลดน้ำหนัก 70% ซึ่งหมายความว่า:

- รถเข็นของคุณเร่งความเร็วได้เร็วขึ้น

- เนินเขากลายเป็นเรื่องง่ายมากขึ้น

- ลดการสึกหรอของยางและช่วงล่างของคุณ

- การควบคุมโดยรวมดีขึ้น

ฉันเคยเห็นรถเข็นเพิ่มความเร็ว 3-5 ไมล์ต่อชั่วโมงเพียงแค่จากการประหยัดน้ำหนักเท่านั้น

พวกมันใช้งานได้เกือบตลอดไป

ดูตัวเลขเหล่านี้:

- แบตเตอรี่ตะกั่วกรด: รอบชาร์จ 500-1,000 ครั้ง

- แบตเตอรี่ลิเธียม: รอบชาร์จ 2,000-5,000 ครั้ง

แปลว่าอะไร? แบตเตอรี่ลิเธียมของคุณสามารถใช้งานได้นาน 8-10 ปี แบตเตอรี่ตะกั่วกรด? คุณโชคดีถ้าได้ 3-5 ปี

และนี่คือจุดสำคัญ:

แบตเตอรี่ลิเธียมรักษาประสิทธิภาพไว้ได้ตลอดเวลา แบตเตอรี่ตะกั่วกรดเริ่มเสื่อมตั้งแต่วันแรก

ไม่ต้องบำรุงรักษาเลย

ยังจำได้ไหมว่าตรวจระดับน้ำ? ทำความสะอาดคราบสนิม? จัดการกับการรั่วไหลของกรด?

ใช่แล้ว ลืมเรื่องเหล่านั้นไปได้เลย

แบตเตอรี่ลิเธียมต้องการการบำรุงรักษาเพียงศูนย์เท่านั้น ติดตั้งแล้วลืมได้เลย

เจ้าของรีสอร์ทคนหนึ่งที่ฉันคุยด้วยประหยัดเวลาในการบำรุงรักษาแบตเตอรี่ได้ 15 ชั่วโมงต่อเดือน หลังจากเปลี่ยนยานพาหนะเป็นลิเธียม

วิธีเลือกแบตเตอรี่ลิเธียมที่เหมาะสมสำหรับรถกอล์ฟ

ไม่ใช่แบตเตอรี่ลิเธียมทุกก้อนที่ถูกสร้างมาเท่ากัน

นี่คือสิ่งที่ควรมองหาอย่างชัดเจน:

ขั้นตอนที่ 1: เลือกแรงดันไฟฟ้าที่ตรงกัน

อันนี้สำคัญมาก

รถกอล์ฟส่วนใหญ่ใช้ระบบไฟฟ้าหรือ:

- ระบบ 36V (รุ่นเก่า)

- ระบบ 48V (เป็นที่นิยมมากที่สุด)

- ระบบ 72V (สมรรถนะสูง)

การติดตั้งแรงดันไฟฟ้าที่ไม่ถูกต้องจะทำให้อิเล็กทรอนิกส์ของรถเสียหาย ควรตรวจสอบการตั้งค่าปัจจุบันของคุณก่อน

คำแนะนำจากมืออาชีพ: มองหาสติ๊กเกอร์ใต้เบาะนั่งหรือเช็คคู่มือเจ้าของรถ

ขั้นตอนที่ 2: เลือกความจุที่เหมาะสม (แอมป์ชั่วโมง)

ความจุเป็นตัวกำหนดระยะทางของคุณ นี่คือคำแนะนำของฉันตามการใช้งาน:

ใช้งานเบา (9-18 หลุม, พื้นราบ)

- ความจุ 60-80Ah

- ระยะทาง: 20-30 ไมล์

ใช้งานปกติ (36 หลุม, มีเนินเขาบ้าง)

- ความจุ 100-105Ah

- ระยะทาง: 35-50 ไมล์

ใช้งานหนัก (ทั้งวัน, สนามเนินเขา)

- ความจุ 150Ah+

- ระยะทาง: 50-70+ ไมล์

คนส่วนใหญ่เลือกใช้ 100Ah สำหรับระบบ 48V นี่คือจุดที่สมดุลระหว่างระยะทางและราคา

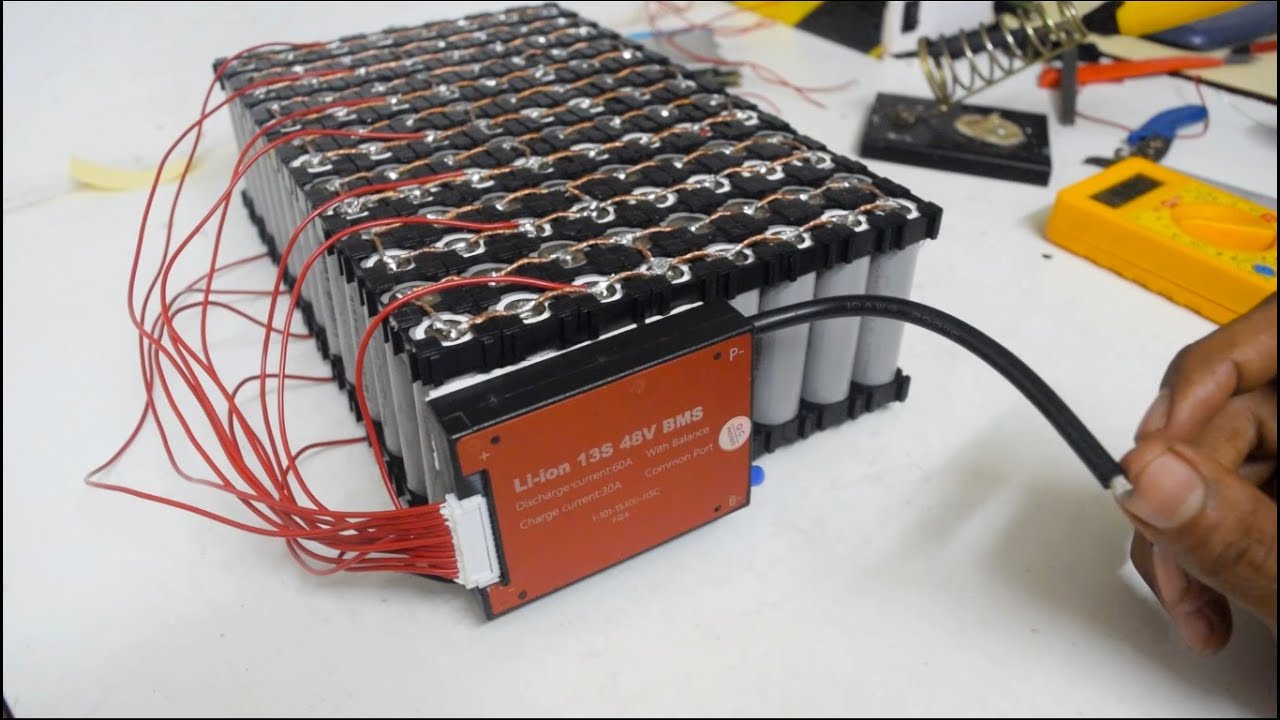

ขั้นตอนที่ 3: ตรวจสอบระบบจัดการแบตเตอรี่ (BMS)

The ระบบบริหารจัดการแบตเตอรี่ (BMS) เหมือนสมองของแบตเตอรี่ของคุณ ระบบที่ดีจะป้องกัน:

- การชาร์จเกิน

- การปล่อยไฟเกิน

- วงจรลัด

- อุณหภูมิที่เกินขีดจำกัด

อย่าประหยัดเกินไปในส่วนนี้ BMS คุณภาพดีสามารถช่วยปกป้องแบตเตอรี่ (และรถเข็นของคุณ) จากความเสียหาย

ตัวเลขสมรรถนะจริงที่สำคัญ

ให้ฉันแบ่งปันข้อมูลทดสอบจริงจากปี 2025:

รถ EZ-GO RXV มาตรฐานพร้อมแบตเตอรี่ตะกั่วกรด:

- ความเร็วสูงสุด: 19.2 ไมล์ต่อชั่วโมง

- ระยะทาง: 28 ไมล์

- ความสามารถปีนเขา: ปานกลาง

รถเข็นเดียวกับแบตเตอรี่ลิเธียม 105Ah:

- ความเร็วสูงสุด: 22.1 ไมล์ต่อชั่วโมง

- ระยะทาง: 48 ไมล์

- ความสามารถปีนเขา: ยอดเยี่ยม

นั่นไม่ใช่คำโฆษณาเท่านั้น ตัวเลขเหล่านี้เป็นตัวเลขในโลกจริง

การติดตั้ง: ง่ายกว่าที่คุณคิด

ฉันรู้ว่าคุณกำลังคิดว่า:

“นี่ดูซับซ้อน”

แต่ความจริงคือ: การแปลงเป็นลิเธียมส่วนใหญ่ใช้เวลา 1-2 ชั่วโมง สูงสุด

กระบวนการพื้นฐาน

- ถอดแบตเตอรี่เก่าออก (ใส่ถุงมือ – มันหนักและอาจรั่วไหลได้)

- ทำความสะอาดถาดแบตเตอรี่ (กำจัดสนิมหรือคราบสกปรก)

- ใส่แพ็คลิเธียมเข้าไป (ส่วนใหญ่ถูกออกแบบให้พอดีอย่างลงตัว)

- เชื่อมต่อสายเคเบิล (สีแดงต่อบวก สีดำต่อลบ)

- ติดตั้งเครื่องชาร์จใหม่ (ลิเธียมต้องการโปรไฟล์การชาร์จที่แตกต่างกัน)

- ทดสอบทุกอย่าง (แรงดันควรอ่านประมาณ 51.2V สำหรับชุดแบตเตอรี่ 48V เต็ม)

แค่นั้นแหละ จริงๆ

หลายแบรนด์เช่น Allied Lithium และ Eco Battery ยังมีวิดีโอสอนทีละขั้นตอน

คำถามเรื่องเงิน: คุ้มค่าหรือไม่?

มาคุยเรื่องเงินและสตางค์กัน

ค่าใช้จ่ายล่วงหน้า:

- ชุดแบตเตอรี่ตะกั่วกรด: $800-1,500

- ชุดลิเธียม: $2,000-3,500

ดูเหมือนแพงใช่ไหม?

แต่ลองดูสิ:

ในระยะเวลา 10 ปี คุณจะซื้อแบตเตอรี่ตะกั่วกรด 2-3 ครั้ง พร้อมอุปกรณ์บำรุงรักษา และค่าไฟฟ้าสิ้นเปลือง (ลิเธียมชาร์จไฟได้มีประสิทธิภาพมากกว่า 40%)

เมื่อคำนวณดูแล้ว ลิเธียมจะประหยัดเงินจริงๆ หลังจากประมาณ 5 ปี

ตัวอย่างจริงจากสนามกอล์ฟในประเทศไทย:

พวกเขาเปลี่ยนรถกอล์ฟ 50 คันเป็นลิเธียมในปี 2023 การลงทุนเริ่มต้น: $125,000

การประหยัดในปี 2025:

- หลีกเลี่ยงการเปลี่ยนแบตเตอรี่: $40,000

- ค่าแรงบำรุงรักษา: $36,000

- ค่าไฟฟ้า: $8,000

พวกเขาได้เปรียบแล้ว $84,000 โดยมีอายุแบตเตอรี่เหลืออีกมากกว่า 5 ปี

ตัวเลือกแบตเตอรี่ลิเธียมไอออนชั้นนำสำหรับรถกอล์ฟ 2025

อิงจากการวิจัยและความคิดเห็นของผู้ใช้ นี่คือจุดเด่น:

ดีที่สุดโดยรวม: Eco Battery 48V 105Ah

- อายุการใช้งาน 5,000 รอบ

- การตรวจสอบผ่านบลูทูธ

- พร้อมใช้งานทันที

- ราคา: $2,800-3,200

คุ้มค่าที่สุด: Bolt Energy 48V 105Ah

- ประสิทธิภาพยอดเยี่ยม

- รับประกัน 10 ปี

- น้ำหนักเพียง 55 ปอนด์

- ราคา: $2,500-2,900

ดีที่สุดสำหรับรถกอล์ฟดัดแปลง: Allied Lithium

- อัตราการปล่อยไฟสูง

- การกำหนดค่าที่ปรับแต่งได้

- ความน่าเชื่อถือที่พิสูจน์แล้ว

- ราคา: $2,200-2,700

ข้อผิดพลาดทั่วไปที่ควรหลีกเลี่ยง

ฉันเคยเห็นคนทำผิดพลาดในการอัปเกรดลิเธียม นี่คือสิ่งที่ไม่ควรทำ:

ข้อผิดพลาด #1: ใช้ที่ชาร์จผิดประเภท

เครื่องชาร์จแบตเตอรี่ตะกั่วกรดจะทำลายแบตเตอรี่ลิเธียม ควรใช้เครื่องชาร์จที่ออกแบบสำหรับลิเธียมโดยเฉพาะเสมอ

ความผิดพลาด #2: การผสมประเภทแบตเตอรี่

อย่าผสมแบตเตอรี่ลิเธียมกับตะกั่วกรดเลย มันอันตรายและจะทำลายทั้งสองแบตเตอรี่

ความผิดพลาด #3: ไม่สนใจขีดจำกัดอุณหภูมิ

อากาศหนาวจัด (ต่ำกว่า 0°F) อาจลดความจุชั่วคราว ควรเก็บรถเข็นของคุณในที่อุ่นขึ้นถ้าเป็นไปได้

ความผิดพลาด #4: ซื้อแบรนด์ไม่มีชื่อ

ควรเลือกบริษัทที่มีชื่อเสียง การใช้ BMS ที่ไม่ดีอาจทำให้เกิดไฟไหม้ได้จริงๆ

อนาคตได้มาถึงแล้ว

ผู้ผลิตรายใหญ่เริ่มให้ความสนใจ

Club Car ตอนนี้มีตัวเลือกแบตเตอรี่ลิเธียมเป็นอุปกรณ์มาตรฐาน Yamaha ก็ทำเช่นเดียวกัน แม้แต่ EZ-GO ก็เข้าร่วมในปี 2024

นั่นบอกทุกอย่างเกี่ยวกับทิศทางของอุตสาหกรรมนี้

เคล็ดลับบำรุงรักษาอย่างรวดเร็ว

แม้ว่าแบตเตอรี่ลิเธียมจะดูแลรักษาง่าย แต่ควรปฏิบัติตามเคล็ดลับเหล่านี้เพื่ออายุการใช้งานสูงสุด:

- ชาร์จหลังใช้งานแต่ละครั้ง (การชาร์จบางส่วนก็ได้)

- เก็บไว้ที่ระดับชาร์จ 50-60% หากไม่ได้ใช้งานเป็นเวลาหลายเดือน

- รักษาการเชื่อมต่อให้สะอาดและแน่นหนา

- อัปเดตเฟิร์มแวร์ BMS หากมีให้

- หลีกเลี่ยงการปล่อยให้แบตเตอรี่หมดสนิทเป็นเวลานาน

อาจใช้เวลาประมาณ 10 นาทีต่อปี

ผลกระทบต่อสิ่งแวดล้อมที่สำคัญจริงๆ

นี่คือสิ่งที่เจ๋ง:

แบตเตอรี่ลิเธียมเป็นมิตรกับสิ่งแวดล้อมมากกว่ากรดตะกั่วอย่างมาก ไม่มีสารตะกั่วที่เป็นพิษ ไม่มีการรั่วไหลของกรด และสามารถรีไซเคิลได้ 95%

ยิ่งไปกว่านั้น เนื่องจากใช้งานได้นาน 3 เท่า คุณจึงสร้างของเสียได้น้อยลงมาก

สนามกอล์ฟแห่งหนึ่งคำนวณว่าจะป้องกันของเสียกรดตะกั่วได้ถึง 12,000 ปอนด์ในทศวรรษหน้าโดยเปลี่ยนมาใช้ลิเธียม

การตัดสินใจของคุณ

สรุปแล้ว?

ถ้าคุณใช้รถเข็นของคุณเป็นประจำและวางแผนที่จะเก็บไว้มากกว่า 3 ปี ลิเธียมก็สมเหตุสมผล

ผลการปรับปรุงประสิทธิภาพเพียงอย่างเดียวก็คุ้มค่าแล้ว รวมถึงการประหยัดในการบำรุงรักษาและอายุการใช้งานที่ยาวนานขึ้น? มันเป็นเรื่องง่ายที่จะตัดสินใจ

เหตุผลเดียวที่ควรอยู่กับกรดตะกั่วคือ:

- คุณใช้งรถเข็นของคุณน้อยมาก

- งบประมาณตอนนี้จำกัดมาก

- คุณจะขายเร็ว ๆ นี้

ถ้าไม่ใช่อย่างนั้น? เปลี่ยนมาใช้เลย

ความคิดสุดท้าย

แบตเตอรี่ลิเธียมสำหรับรถกอล์ฟ การเปลี่ยนแปลงเป็นหนึ่งในการอัปเกรดที่สมเหตุสมผลที่สุด

ประสิทธิภาพดีกว่า ง่ายขึ้น ค่าใช้จ่ายระยะยาวต่ำลง

ฉันยังไม่เคยพบใครที่เสียใจที่เปลี่ยนมาใช้ แต่ฉันพบหลายคนที่เสียดายที่ไม่ได้ทำมันเร็วกว่านี้

เทคโนโลยีได้รับการพิสูจน์แล้ว ราคาเป็นเหตุผลได้ และประโยชน์ก็เห็นได้ทันที

คุณรออะไรอยู่?