Are you planning to expand your off-grid power but worried about the Wiring Batteries in Parallel Danger? Increasing your capacity sounds simple, but a single mistake in a battery bank setup can lead to thermal runaway, melted cables, or even a total system fire.

Whether you’re upgrading an RV, outfitting a boat, or building a solar array, you need more than just a basic connection. You need safety protocols that protect your investment and your home.

In this comprehensive guide, you’ll learn the exact risks of parallel wiring, from voltage mismatch to imbalanced currents, and how to set up your LiFePO4 batteries for maximum longevity. We’ve been perfecting power solutions since 2012, and we’re sharing the best practices to keep your system running safely.

Let’s dive right in.

Wiring Batteries in Parallel Danger: A Comprehensive Safety Guide

Understanding Parallel Battery Connections

When I design power systems for RVs or off-grid cabins, I focus on two ways to hook up batteries: parallel and series. To avoid the specific risks associated with wiring batteries in parallel danger, you first need to understand what this configuration actually does to your power bank.

In a parallel configuration, you connect the positive terminal of one battery to the positive terminal of the next, and do the same with the negatives. This increases your total capacity (Amp-hours) while the voltage stays the same. If you have two 12V 100Ah Nuranu LiFePO4 batteries in parallel, you get a 12V 200Ah bank.

Parallel vs. Series: Quick Comparison

| Feature | Parallel Connection | Series Connection |

|---|---|---|

| Wiring Method | Positive to Positive / Negative to Negative | Positive to Negative |

| Voltage (V) | Stays the Same (e.g., 12V) | Increases (e.g., 12V + 12V = 24V) |

| Capacity (Ah) | Increases (e.g., 100Ah + 100Ah = 200Ah) | Stays the Same (e.g., 100Ah) |

| Main Benefit | Longer Runtime (Increased Scale) | Higher Power Efficiency for Large Inverters |

Why Choose Parallel for Low-Voltage Systems?

Parallel wiring is the go-to choice for most 12V and 24V mobile systems. It provides several key advantages for users who need reliable, long-term energy storage:

- Greater Runtime: By stacking Amp-hours, you can run your lights, refrigerators, and electronics for days without needing a recharge.

- System Scalability: It allows you to expand your energy reservoir as your power needs grow, provided you follow strict safety protocols.

- Redundancy: In a parallel bank, if one battery requires maintenance, the others can often continue to provide power to your critical loads.

- Low-Voltage Safety: Keeping the system at 12V or 24V reduces the risk of high-voltage arcing compared to high-voltage series strings.

While the benefits of increased runtime are clear, the danger of wiring batteries in parallel arises during the installation phase. If the batteries aren’t matched perfectly in voltage and state of charge, you risk massive current surges that can damage your equipment or compromise the Integrated BMS found in high-performance LiFePO4 units.

The Critical Risks of Parallel Battery Connections

Wiring batteries in parallel is a common way to increase your system’s capacity, but it introduces significant parallel battery connection risks if handled incorrectly. Because you are dealing with high energy density, mistakes can lead to hardware destruction or fire.

Voltage Mismatch and State of Charge (SoC) Imbalance

Connecting batteries with different charge levels is one of the most common voltage mismatch hazards. If one battery is at 13.6V and the other is at 12.0V, the higher-voltage battery will dump current into the lower-voltage one at an extremely high rate. This “current rush” can exceed the battery’s maximum charge rating, causing the terminals to spark or the internal components to fail. Proper state of charge matching is required before any physical connection is made to ensure the batteries are balanced.

Mixing Battery Types, Ages, or Capacities

A healthy battery bank requires uniformity. Mixing different chemistries, such as lead-acid with lithium, is dangerous because they have different charging profiles and internal resistances. Even mixing old and new LiFePO4 batteries causes a battery bank imbalance. Older cells have higher internal resistance, which forces the newer batteries to shoulder the entire load, leading to premature wear and potential overheating of the fresh units.

Current Imbalance from Uneven Wiring

Electricity always follows the path of least resistance. If you use cables of different lengths or gauges between your batteries, the current will not be distributed equally. This uneven cable lengths danger means the battery with the shortest path will work significantly harder than the others. Over time, this specific battery will overheat and fail, potentially triggering a chain reaction across the rest of the bank.

Overheating and Thermal Runaway

High-performance systems generate heat, and in a parallel configuration, that heat can compound quickly. While we prioritize the fact that LiFePO4 batteries are safe due to their stable chemistry, a massive short circuit in a high-amp bank can still lead to thermal runaway prevention failure. Without a smart BMS or proper fusing, a single cell failure can cause the entire bank to vent or catch fire.

Common Parallel Hazards at a Glance:

- Short Circuits: High-energy discharge that can instantly vaporize metal tools or wires.

- Melting Insulation: Occurs when the cable gauge for battery bank setups is too thin for the total combined amperage.

- Overcurrent Surges: Rapid current flow that can bypass internal safety resets if not fused externally.

- Arcing: Occurs when connecting batteries with a significant voltage delta, potentially damaging the battery posts.

Essential Safety Rules to Prevent Wiring Batteries in Parallel Danger

Before you start connecting your bank, you must follow these non-negotiable safety protocols. Most issues with wiring batteries in parallel danger stem from skipping these preparation steps. To keep your system stable and safe, we require these four rules:

- Use Identical Batteries Only: Never mix brands, capacities (Ah), or chemistries. Your batteries should ideally be from the same production batch. Mixing a new battery with an old one causes the older unit to resist charging, forcing the new one to do all the work. Understanding how long LiFePO4 batteries last will help you see why starting with a fresh, matched set protects your long-term investment.

- State of Charge Matching: You must synchronize the voltage of every unit before they are linked. We recommend charging each battery individually to 100% first. If you connect a fully charged battery to a depleted one, a massive “current rush” occurs. This voltage mismatch hazard can trigger the BMS to shut down or, in extreme cases, damage the internal terminals.

- Correct Cable Gauge for Battery Bank: Your wiring must be rated for the total maximum current of the entire bank, not just a single battery. Using undersized wires leads to resistance, heat buildup, and melted insulation. We advocate for high-quality, thick-gauge copper cables to ensure even power distribution.

- Install Overcurrent Protection Fuses: Never wire a system without fuses or circuit breakers between the batteries and the load. This is your primary defense against short circuits.

A common mistake is trying to save money by combining different cell types. We’ve detailed the technical risks of this in our guide on whether you can mix 18650 batteries, and the same principles of internal resistance and balance apply to larger LiFePO4 banks.

Pre-Connection Safety Checklist

| Requirement | Action Step |

|---|---|

| Voltage Check | Ensure all units are within 0.1V of each other. |

| Visual Inspection | Check for casing cracks or terminal corrosion. |

| Torque Specs | Use a torque wrench to ensure tight, secure terminal connections. |

| Environment | Ensure the area is dry and ventilated to prevent heat trapping. |

By strictly adhering to these rules, you eliminate the most common causes of system failure and ensure your LiFePO4 setup operates at peak efficiency without safety compromises.

Best Practices for Safe Parallel Wiring

To minimize the wiring batteries in parallel danger, you must ensure that current flows equally through every unit in your bank. If the resistance is uneven, one battery will discharge faster and work harder, leading to premature failure and safety risks. Following these industry-standard methods ensures your LiFePO4 parallel wiring safety remains intact.

Diagonal Wiring for Small Banks

For systems involving two or three batteries, we recommend diagonal battery wiring. Instead of connecting your main positive and negative cables to the same battery, connect the positive lead to the first battery in the group and the negative lead to the last. This technique forces the electrical current to pass through an equal length of cable for each battery, preventing a battery bank imbalance.

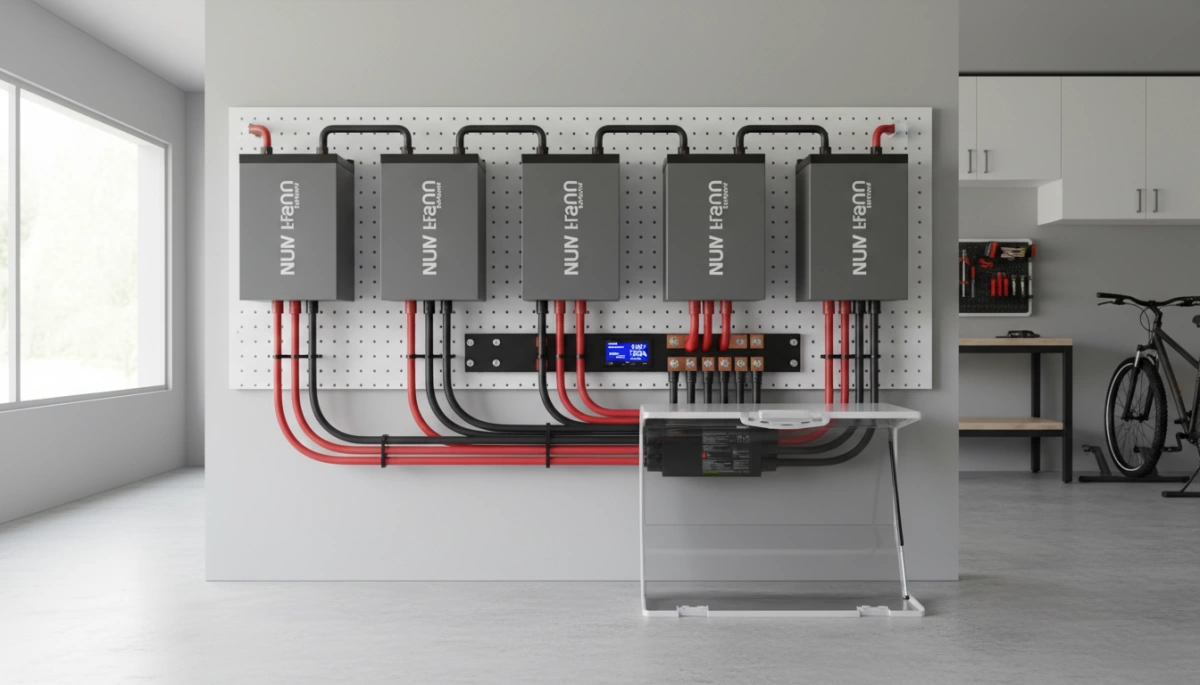

Busbar Parallel Connections for Large Setups

When your energy needs grow beyond three batteries, standard cabling becomes inefficient. We use busbar parallel connections to maintain system integrity. A solid copper busbar provides a central, low-resistance point for all connections. This ensures that the cable gauge for battery bank requirements is met and that every battery “sees” the exact same voltage and load.

The Role of the Integrated BMS and Monitoring

A high-quality battery management system (BMS) is your most important safety feature. In our Nuranu LiFePO4 units, the BMS automatically balances cells and protects against over-current during parallel operation. However, you should still use external monitoring tools:

- Smart Shunts: Use a shunt to monitor the total State of Charge (SoC) of the entire bank.

- Voltage Meters: Regularly check individual battery voltages to ensure they stay synchronized.

- Terminal Inspection: Before securing connections, always identify the positive and negative electrodes correctly to prevent a dead short.

Essential Wiring Checklist

- Equal Lengths: All interconnecting cables must be the exact same length and gauge.

- Clean Contacts: Ensure all terminals are free of corrosion and torqued to the manufacturer’s specifications.

- Overcurrent Protection: Install overcurrent protection fuses between the battery bank and your inverter to prevent thermal events.

Why Nuranu LiFePO4 Batteries Excel in Parallel Configurations

Since 2012, we have specialized in high-performance energy storage. We understand that managing the Wiring Batteries in Parallel Danger: A Comprehensive Safety Guide starts with the internal hardware. Our LiFePO4 systems are engineered to handle the specific stresses of parallel expansion, ensuring your power bank remains stable and efficient.

Integrated Smart BMS Technology

The Battery Management System (BMS) is the brain of our battery. In a parallel setup, it actively monitors the voltage and temperature of each unit. If it detects a voltage mismatch hazard or an over-current situation, the BMS triggers an immediate shutdown of that specific unit. This prevents the “current rush” effect and significantly reduces lithium battery fire risks.

Superior Cell Consistency

We use only Grade A LiFePO4 cells in our manufacturing process. High-quality cells are critical because they maintain nearly identical internal resistance across multiple units. When designing and manufacturing lithium batteries, we prioritize this consistency to prevent battery bank imbalance, where one battery works harder than the others and fails prematurely.

Built for Harsh Environments

- IP-Rated Waterproofing: Our rugged casings prevent moisture from causing internal shorts, a common concern in marine and RV applications.

- Thermal Stability: The LiFePO4 chemistry we use is inherently safer and more stable than traditional lithium-ion, making it ideal for high-capacity parallel banks.

- Optimized Scaling: Nuranu batteries are designed for synchronized protection, supporting parallel expansion up to 4 units while maintaining total system safety.

Reliability You Can Trust

Our focus on safety and longevity ensures that your investment provides a 10+ year service life. By using advanced protection protocols, we eliminate the guesswork and technical risks typically associated with LiFePO4 parallel wiring safety.

Common Mistakes to Avoid in Parallel Wiring

Even with the best equipment, simple installation errors can amplify parallel battery connection risks. I have seen many setups fail prematurely because of these avoidable oversights:

- Daisy-Chaining High-Amperage Systems: Connecting batteries one after another in a simple line is a recipe for disaster. This creates high resistance at the end of the chain, causing a severe battery bank imbalance where the first battery wears out much faster than the rest.

- Ignoring Overcurrent Protection: Skipping the fuses is a massive safety gamble. Without overcurrent protection fuses on each parallel branch, a single internal short can trigger a chain reaction, making thermal runaway prevention nearly impossible.

- Mismatched Cable Lengths: Current always follows the path of least resistance. The uneven cable lengths danger means that even a few extra inches of wire on one battery will cause it to underperform, while others are overworked.

- Connecting During Active Charging: Never add a battery to your bank while the system is under load or being charged. This can cause massive arcing and sudden voltage spikes that damage sensitive electronics.

To maintain LiFePO4 parallel wiring safety, your wiring must be as consistent as your cells. If you are upgrading your power storage, using a high-quality LiFePO4 battery is a great start, but your wiring discipline is what keeps the system running for years without failure. Always use identical cable gauges and double-check every connection before flipping the switch.

Frequently Asked Questions About Parallel Battery Safety

Navigating the complexities of Wiring Batteries in Parallel Danger: A Comprehensive Safety Guide often leads to specific technical questions. Below are the most common concerns we address to ensure your power system remains stable and efficient.

Can I parallel batteries with different capacities?

No. You should never mix batteries of different Amp-hour (Ah) ratings. Connecting a 100Ah battery to a 200Ah battery causes the smaller unit to work significantly harder, leading to faster degradation and battery bank imbalance. To maintain safety, always use batteries of the same capacity, brand, and age.

How many batteries can I safely connect in parallel?

For our LiFePO4 systems, we generally recommend a maximum of four units in parallel. Exceeding this limit increases the risk of current imbalance from uneven wiring and makes it harder for the battery management system (BMS) to synchronize protection across the entire bank. If you need more capacity, it is often safer to move to a higher-capacity individual unit.

What happens if one battery in the bank fails?

If one battery fails or experiences a cell collapse, the other batteries in the parallel configuration will immediately dump their current into the faulty unit. This creates a high-heat scenario. However, our integrated BMS acts as a fail-safe, disconnecting the compromised unit before it can trigger a thermal event. Regular maintenance, such as knowing how to charge the 26650 LiFePO4 battery or larger blocks correctly, helps prevent these failures.

Is a parallel configuration safer than a series setup?

Parallel wiring is often viewed as safer for DIY users because it keeps the system at a lower, safer-to-touch voltage (like 12V or 24V). However, the LiFePO4 parallel wiring safety concerns shift toward high amperage. While series setups face high-voltage arcing risks, parallel setups face higher risks of melting cables and short circuit in parallel batteries due to the massive combined current potential.

Should I use a fuse for every battery in the bank?

Yes. We strongly recommend individual fusing for each battery branch before they meet at a common busbar. This ensures that if one battery develops a short, the fuse will blow and isolate that specific unit, protecting the rest of your investment from catastrophic damage.