D Battery Guide What It Is and Its Standard Voltage Explained

You’ve likely relied on a D battery to power a heavy-duty flashlight or a boombox during a power outage.

But do you know exactly what makes this large cylindrical dry cell tick?

Many assume that because it is significantly larger than an AA cell, it must pack a higher voltage.

That is actually a myth.

In this guide, I’m going to break down everything you need to know about D battery voltage, its massive capacity, and why it remains the king of high-drain devices.

From standard IEC R20 specifications to the differences between alkaline, NiMH, and modern lithium alternatives, you’ll get the technical facts without the fluff.

Let’s dive right in.

What Exactly Is a D Battery?

If you have ever handled a heavy-duty flashlight or a portable radio, you know exactly what a D cell battery is. Introduced back in the late 1890s, this battery size—technically known as the IEC R20 battery—has remained a staple for high-energy applications where weight and size are less critical than raw runtime. Unlike the slim cells used in modern smartphones, the D battery is a large cylindrical dry cell built to hold a massive amount of chemical energy.

Standard Physical Specifications

Let’s look at the hard numbers. In the battery world, precision matters. A standard D size battery is defined by specific dimensions that ensure it fits into everything from megaphones to Geiger counters:

- Diameter: 33.2 mm (often measuring up to 34.2 mm depending on the casing).

- Length: 61.5 mm.

- Weight: These are heavy hitters, weighing between 135g and 200g depending on whether you are using Alkaline or NiMH chemistry.

Visual Comparison: The “Fuel Tank” Analogy

To understand the D battery, you have to compare it to its smaller siblings. While a D cell often shares the same voltage as a AA or C battery, the physical difference is substantial.

Think of it this way: if a AA battery is a small water bottle, the D battery is a 5-gallon jug. It is significantly wider and heavier than the C cell (Size R14) and dwarfs the standard AA. This extra physical volume allows the D battery to pack much more anode and cathode material inside, which translates directly to higher capacity and longer runtimes in high-drain devices.

D Battery Voltage Explained

Let’s get straight to the numbers. For the vast majority of consumer applications, the nominal voltage of a standard Alkaline D battery is 1.5V. If you take a fresh cell right out of the package and test it with a multimeter, you will likely see an open-circuit reading closer to 1.6V, but this settles down quickly once the battery is under load.

A common misconception I encounter is the idea that a bigger battery equals more voltage. That is not the case. A tiny AAA and a massive D cell battery often share the exact same chemistry, meaning their electrical potential is identical. The physical size difference is strictly about capacity (mAh)—think of the D cell as having a massive fuel tank compared to the AAA’s shot glass, allowing it to run longer, not harder.

However, chemistry dictates voltage, so you need to pay attention to the specific type you are buying:

- Alkaline & Zinc-Carbon: Standard 1.5V.

- NiMH Rechargeable: Typically 1.2V nominal voltage. While lower, these maintain their voltage better under heavy loads than alkalines.

- Lithium Primary (Industrial): Specialized Lithium D cell 3.6V options exist (often Li-SOCl2). Warning: Do not put these in a standard radio or flashlight; the excess voltage will fry your device.

If you are exploring high-performance energy storage, modern lithium-ion battery products are often replacing these older form factors in custom builds due to superior energy density, provided the voltage is managed correctly.

Capacity and Performance: Why D Batteries Pack More Power

Let me be straight with you: the size of a battery doesn’t determine its voltage, but it definitely dictates how long it will run. While a D cell shares the same 1.5V nominal voltage as a standard AA, the difference lies entirely in the D battery capacity mAh. Think of voltage as the water pressure and capacity as the size of the water tank. A D battery is a massive tank compared to its smaller siblings, holding significantly more chemical energy inside that large cylindrical dry cell.

Typical Capacity by Chemistry

The actual runtime you get depends heavily on the chemistry inside the can. I’ve tested countless cells, and here is the breakdown:

- Alkaline D Batteries: These are the workhorses, typically offering 12,000 to 18,000 mAh. They are ideal for low-to-moderate drains over long periods.

- NiMH Rechargeable: These vary wildly. Some are just AA cells inside a D shell (2,000 mAh), while high-quality true D cells can reach 10,000 mAh.

- Carbon-Zinc: The budget option, usually topping out around 8,000 mAh. I rarely recommend these for modern gear.

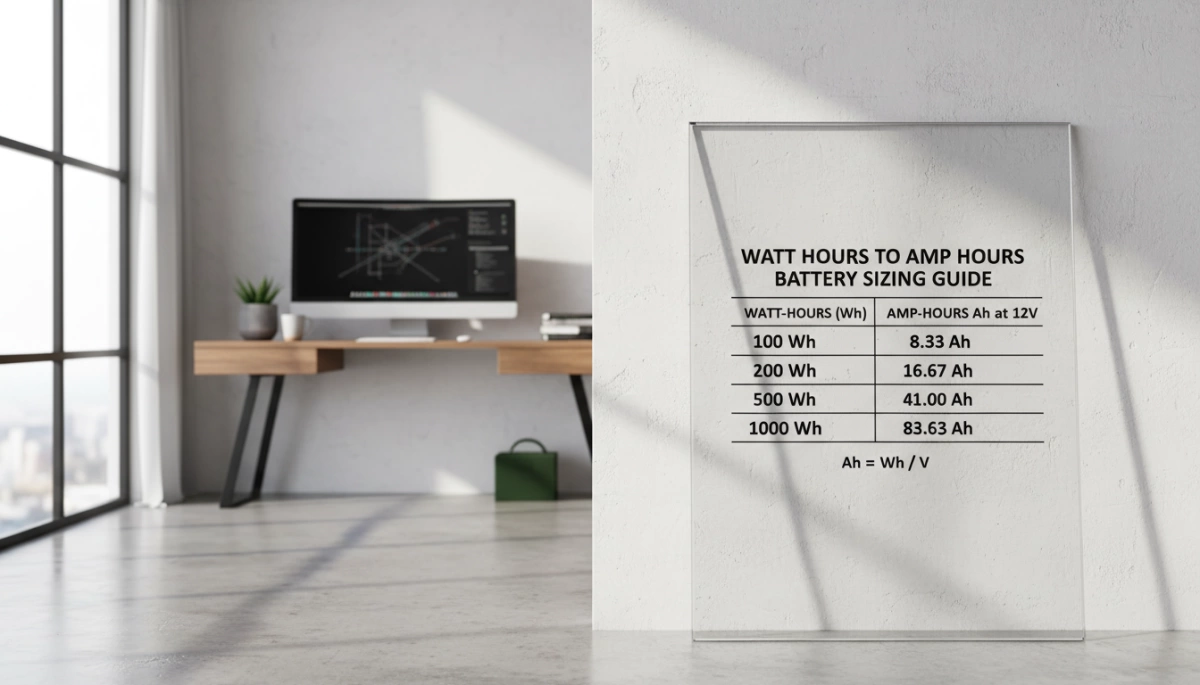

Comparison: D Battery vs C Battery vs AA

To visualize why you would choose the bulkier option for high-drain battery applications, look at the energy density differences below.

| Battery Size | Nominal Voltage | Typical Capacity (Alkaline) | Relative Energy |

|---|---|---|---|

| AA | 1.5V | ~2,500 mAh | 1x (Baseline) |

| C | 1.5V | ~8,000 mAh | ~3.2x AA |

| D | 1.5V | ~18,000 mAh | ~7.2x AA |

When comparing a D battery vs AA battery, the D cell provides roughly 6 to 7 times the runtime in the same device, assuming the device can physically fit it. This is why heavy-duty flashlights and megaphones rely on them; an AA would die in minutes under those loads.

Factors Affecting Real-World Performance

Capacity numbers on the label are best-case scenarios. In the real world, three main factors kill your runtime:

- Discharge Rate: Drawing high current causes voltage sag. A battery discharge curve for an alkaline cell drops steeply under heavy load, meaning you might not get the full 18,000 mAh if you are powering a high-wattage motor.

- Temperature: Cold weather increases internal resistance. If you are using gear in freezing temps, expect significant capacity loss.

- Cut-off Voltage: Some devices stop working once the battery hits 1.1V, while others drain it down to 0.8V. If your device is sensitive to voltage drops, you might think you have a bad battery when it actually has plenty of capacity left, just at a lower voltage.

Common Types of D Batteries and Their Best Applications

When you are shopping for power, you need to match the chemistry to the job. Not all D cells behave the same way, and mixing them up can lead to poor performance or damaged gear. Let me break down the three main contenders you will run into.

Alkaline D Battery (Standard Consumer Choice)

This is the standard cylinder you find in grocery stores. An Alkaline D battery provides a nominal voltage of 1.5V and is designed for a long shelf life. These are the go-to for high-drain battery applications that sit idle for a while before being used, like heavy-duty Maglites, boomboxes, or emergency radios. They deliver reliable power, but once the voltage sags, they are done.

NiMH Rechargeable D Battery

If you are burning through disposables, Nickel-Metal Hydride (NiMH) is the common rechargeable swap. You need to know that these have a nominal voltage of 1.2V, which is lower than alkaline. While they are cost-effective for high-usage devices like toys, the lower voltage might make some older incandescent flashlights look a bit dimmer.

Lithium D Cell 3.6V (Industrial & Specialized)

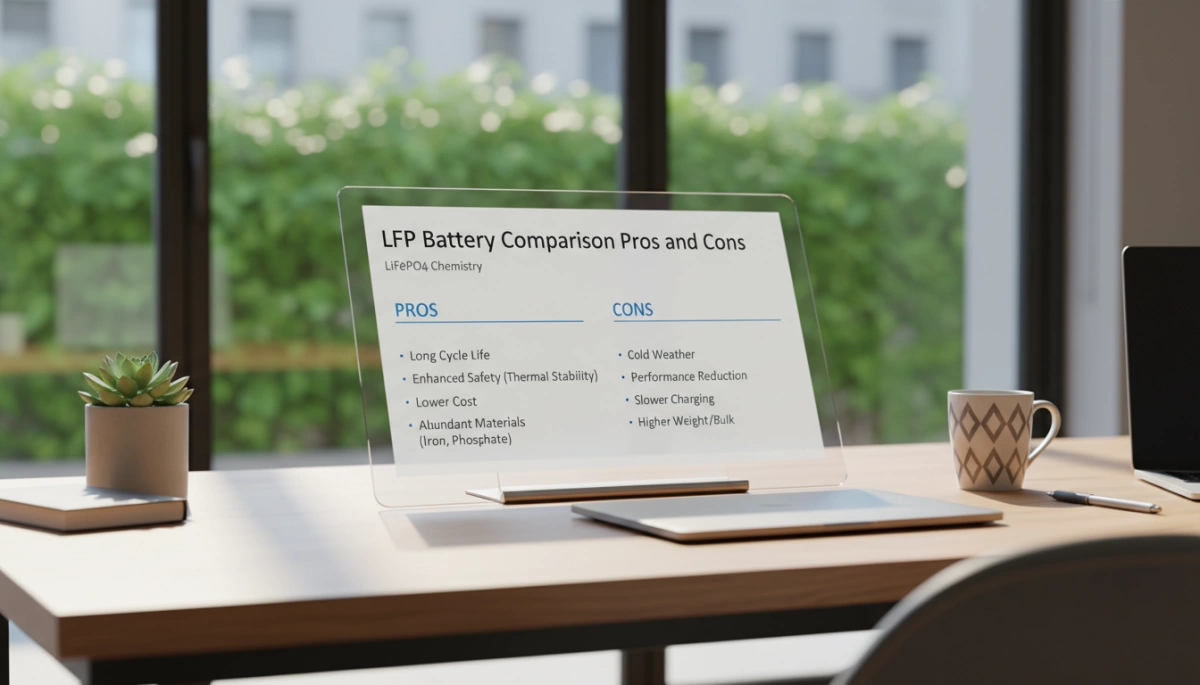

Here is where you need to be careful. There are primary lithium D cells (specifically Lithium Thionyl Chloride) that output a massive 3.6V. These are not direct replacements for standard 1.5V alkaline cells. If you put a Lithium D cell 3.6V into a standard radio, you will likely fry the electronics. These are strictly for industrial metering, medical equipment, and extreme temperature environments. For users looking for high-performance rechargeable solutions without the voltage risk, we often recommend looking into LiFePO4 battery packs as a modern upgrade for heavy-duty setups.

Practical Use Cases Checklist

To get the best performance and avoid damaging your electronics, stick to these applications:

- Alkaline: Megaphones, portable fans, and emergency backup kits.

- NiMH: Remote control vehicles and frequently used camping lanterns.

- Lithium (3.6V): Smart utility meters, memory backup, and professional medical devices.

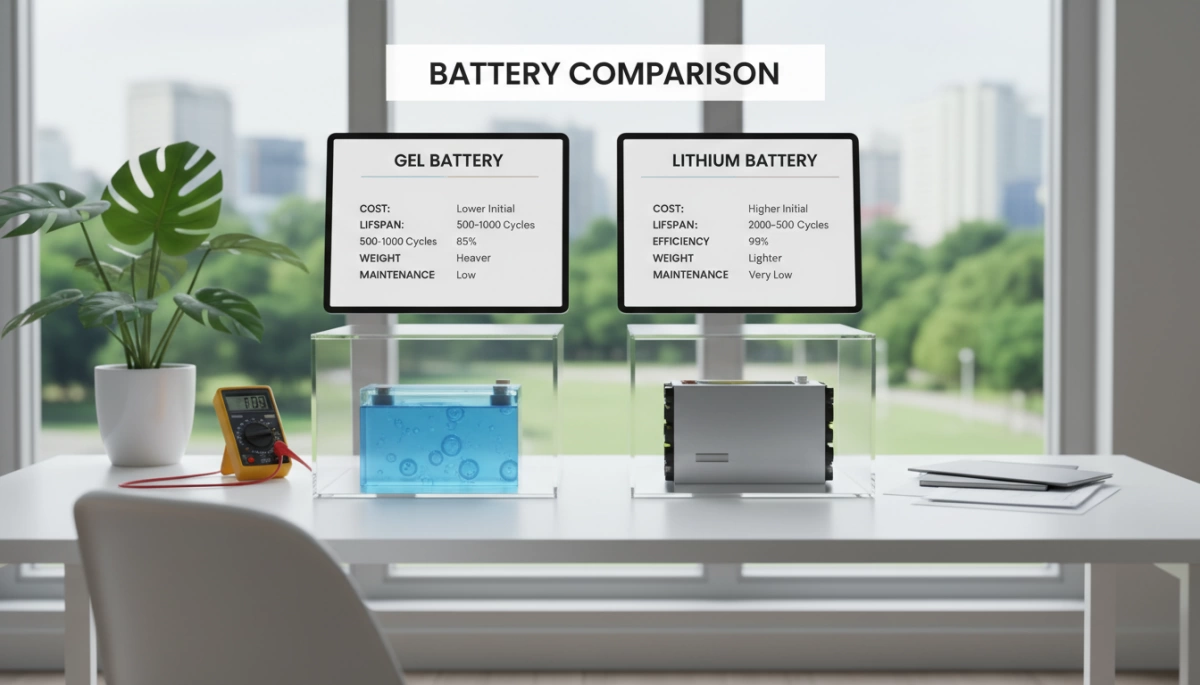

The Modern Alternative: Lithium Batteries vs. Traditional D Cells

Let me be straight with you: if you are still relying exclusively on disposable alkaline D batteries for high-demand applications, you are likely wasting money and carrying dead weight. While the traditional D cell battery has been the standard for decades, modern lithium technology has completely outpaced it in terms of energy density and efficiency.

Key Advantages of Lithium Technology

When I compare alkaline D battery performance against lithium equivalents, the difference is night and day. Lithium chemistries (like Li-ion or LiFePO4) offer a significantly flatter battery discharge curve, meaning they provide consistent power right until they are empty, unlike alkaline cells that lose voltage steadily.

- Weight Reduction: Lithium cells are up to 70% lighter than their alkaline counterparts. This is a massive benefit for portable high-drain battery applications like mega-flashlights or portable audio gear.

- Temperature Performance: Alkaline cells struggle in freezing temps. A Lithium D cell 3.6V (often used in industrial metering) or a consumer-grade lithium rechargeable performs reliably in extreme cold and heat.

- Shelf Life: Lithium batteries have a much lower self-discharge rate, making them ideal for emergency kits that sit idle for years.

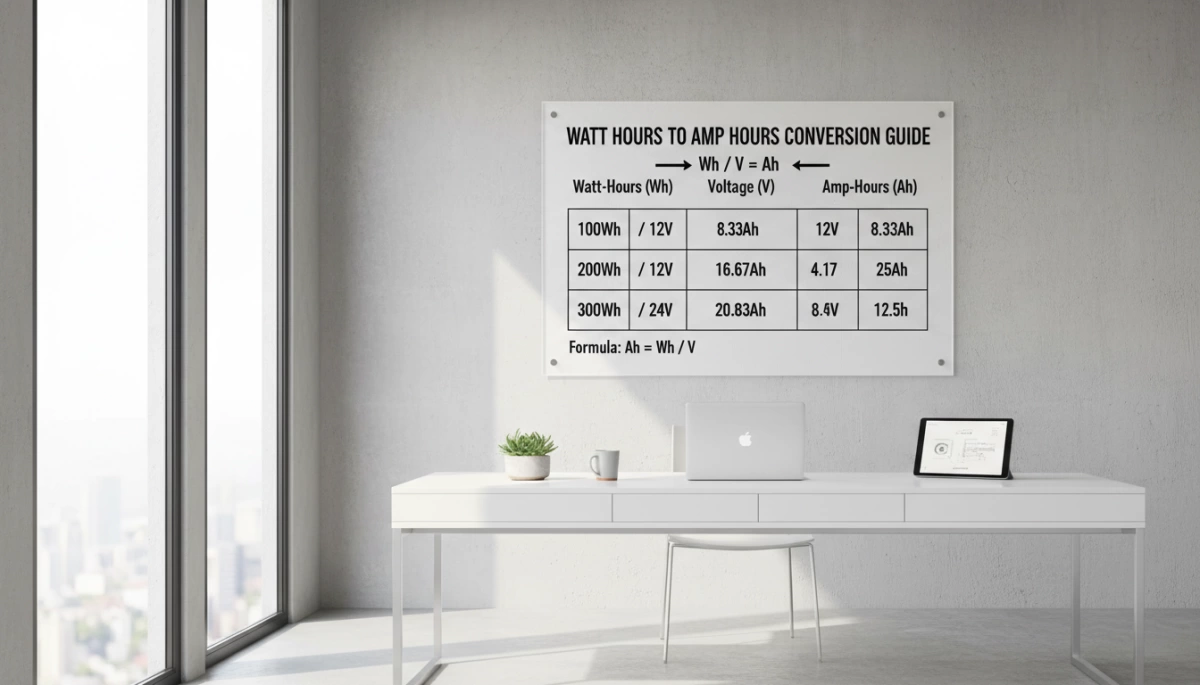

Comparison: Alkaline vs. Advanced Lithium Solutions

The most critical difference lies in longevity and cost-effectiveness. An alkaline D cell is single-use. Once that chemical reaction is done, it goes in the trash. In contrast, modern lithium solutions—especially when scaling up to larger power banks—offer thousands of recharge cycles.

| Feature | Traditional Alkaline D | Lithium / LiFePO4 Solution |

|---|---|---|

| Nominal Voltage | 1.5V (drops under load) | 1.5V (Regulated) or 3.2V/3.7V |

| Cycle Life | Single-Use (1 Cycle) | 2,000 – 5,000+ Cycles |

| Energy Density | Low (Heavy/Bulky) | High (Compact/Light) |

| Voltage Sag | Significant under load | Minimal / Consistent |

Ideal Scenarios for Upgrades

For heavy-duty users, swapping out banks of disposable D cells for a rechargeable system is a smart move. In scenarios like marine electronics, RV power, or solar setups, moving away from heavy dry cells to a dedicated 12V lithium battery system ensures you get consistent voltage and massive capacity without the bulk. This upgrade is essential for anyone prioritizing reliability and long-term value over the initial low cost of disposable batteries.

How to Test and Maintain D Batteries

I can’t stress this enough: stop guessing if your batteries are dead by bouncing them on the table. To get real answers, you need to use a multimeter. While I often discuss the strict voltage requirements of 18650 lithium-ion batteries, testing a standard D cell battery is straightforward, but you still need to know the numbers.

Set your multimeter to DC voltage and touch the probes to the terminals. Here is the breakdown of what the numbers mean for a standard Alkaline D battery:

- 1.5V – 1.6V: Fresh and ready for high-drain applications.

- 1.3V – 1.4V: Partially used. Fine for low-drain devices like radios, but might struggle in high-powered flashlights.

- Below 1.2V: Effectively dead for heavy loads.

Storage and Safety Best Practices

Proper maintenance extends shelf life and prevents damage to your devices. Heat is the enemy of any battery chemistry. Store your IEC R20 battery stock in a cool, dry place (around 60°F–70°F). Avoid the refrigerator; condensation can lead to corrosion.

Follow these safety rules to avoid leaks:

- Never Mix Brands or Ages: Mixing a fresh cell with an old one causes the new battery to force energy into the depleted one, leading to leaks or ruptures.

- Remove Dead Cells Immediately: An empty Alkaline D battery is prone to leaking potassium hydroxide, which will destroy battery contacts.

- Check Terminals: Before installation, ensure the contacts on both the battery and the device are clean and free of corrosion.

Frequently Asked Questions

Let’s clear up the confusion. I get asked these questions constantly by folks trying to figure out if they can swap chemistries or why their device isn’t running right. Here is the straight talk on D battery specifics.

Are all D batteries 1.5V?

No, and assuming they are can be dangerous. While the standard alkaline D battery and zinc-carbon types sit at a nominal voltage 1.5V, that isn’t the rule for every chemistry.

- NiMH Rechargeable: These typically run at 1.2V.

- Lithium (Primary): Industrial Lithium D cell 3.6V batteries (like Li-SOCl2) exist and are meant for specialized equipment, not your boombox.

- LiFePO4: Some modern replacements operate at 3.2V.

Always check the label. Putting a 3.6V cell into a device built for 1.5V will likely fry the electronics.

Can I use rechargeable D batteries in devices designed for alkaline?

In most cases, yes. A NiMH rechargeable D battery operates at 1.2V, which is slightly lower than the 1.5V of an alkaline. However, because alkaline voltage drops as it depletes (often going below 1.2V quickly), most devices are designed to handle this lower voltage range. You might notice a slightly “dimmer” start in unregulated flashlights, but they generally work fine.

What’s the difference between C and D batteries?

It comes down to physical size and fuel tank size, not voltage.

- Voltage: Both are typically 1.5V.

- Capacity: This is the D battery vs C battery differentiator. A D cell is physically larger (Size R20), allowing it to hold significantly more chemical energy.

- Result: A D battery will run much longer under the same load compared to a C battery.

Are lithium D cells a direct replacement for standard alkaline?

This is tricky. If you buy specific “1.5V Lithium” replacements designed for consumer electronics, yes. These often have internal circuitry to regulate the voltage down. However, if you grab a raw industrial lithium cell, you risk damage. When looking at modern upgrades, it is worth understanding the pros and cons of Lithium Iron Phosphate (LFP) batteries to see if that chemistry suits your specific high-drain application better than standard disposable cells.